Solution

Logistics

Optimal Sequencing in Container Terminals

Smoothing overall operations across all vessels.

One of the ports is located in Shenzhen China. It has a total waterfront length of eight kilometers, a yard area of 373 hectares and 16 deep-water container berths. It is equipped with over 70 quay cranes and moves around 80 million TEU( twenty-foot equivalent units) yearly.

The second port is situated in the Kwai Tsing container port area of Hong Kong, one of the busiest container ports in the world. The port operator conducts twelve berths at Terminals 4, 6, 7 and 9.

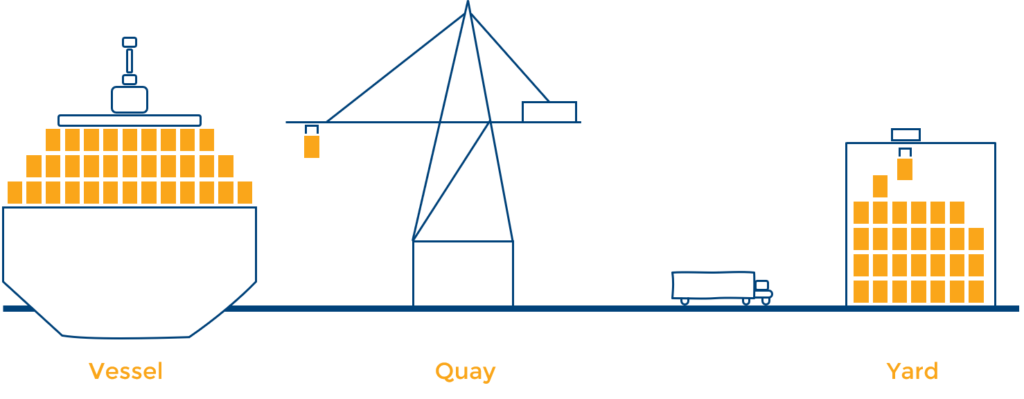

Container terminals logistics solutions need to consolidate and analyze real-time data from operations, apply a scientific approach to decision-making and orchestrate execution and problem resolution. Since Yard bottlenecks are shared across vessels, a multi-vessel view is necessary to smooth operations, and that’s where most packaged solutions fail.

Before implementing DecisionBrain solution, the port operator planned their operations on a single-vessel tool, not considering the impact on the other vessels’ operations. This led to:

- Lack of coordination between Quay and Yard Cranes

- Congestions and delays on loading/discharging

- High Reshuffling

- Traffic jam and Yard clashes during peak hours

- Cranes capacity constraints not respected

- Ships delays due to planning errors

DecisionBrain solution significantly improved the load/discharge balance and reduced the Yard Clash by 70%

Our solution significantly improved the coordination between the Quay side and the Yard side by optimizing load/discharge operations of all vessels:

- Multi-Vessel Optimization: Improve the coordination between the Quay side and the Yard side by holistically optimizing the load/discharge operations of all vessels. Minimize Yard Clash and Traffic Jam while respecting ETD constraints and limiting Reshuffling.

- Load Sequencing: Define the loading sequence of containers from the yard to the vessels. Minimize Yard Clash, Traffic Jam, and Reshuffling while respecting “loadability” constraints.

Port diagram that illustrates the operations between the vessel, quay and yard.

Significant improvements were achieved with the use of the new solution:

- Reduced Yard Clash by 70%

- Reduced movements in the Port

- Reduced Reshuffles by 15%

- Reduced traffic jams and Yard clashes during peak hours

- Improved load/discharge balance