Overview

Optimizing Asset Maintenance with AI and IoT

A global leader in the Distributed Assets industry, sought to improve their maintenance planning process by moving away from frequency-based scheduling and adopting a more data-driven, outcome-based approach. They recognized that not all units in all locations experience the same rate of performance degradation or are used at the same frequency, and they wanted to ensure that their maintenance plans are optimized for each individual asset. DecisionBrain implemented an optimization-powered maintenance system that dynamically adapts the plans to the real usage of each specific asset. We leverage IoT data and predictive maintenance tools to generate operationally efficient maintenance plans while satisfying all contractual and legal constraints.

Challenges

Overcoming Inefficiencies in Static Maintenance Scheduling

The company’s existing maintenance planning system faced challenges in meeting evolving operational requirements and the company’s business goals. It was generating static maintenance plans with significant limitations. Maintenance plans were created based on generalized equipment “profiles” and lacked flexibility. Once defined, these plans remained unchanged over time, often resulting in inefficient calendar-based maintenance that failed to adapt to the actual needs of each equipment.

The static approach also ignored critical factors such as equipment usage patterns and maintenance history. Although IoT data was available, a static, frequency-based planning system is not adequate to leverage signals from this technology. This inability to incorporate equipment-specific data made optimizing maintenance plans or responding dynamically to equipment conditions challenging.

Furthermore, the planning processes and standard operating procedures varied globally, with some regions relying on spreadsheets and other outdated tools. This lack of standardization led to fragmented practices, making it difficult for the organization to ensure transparency, cohesion, and consistent service quality across countries. There was a pressing need for the global organization to take ownership and enforce a unified planning approach.

Solution

Dynamic Maintenance Planner: A Fully Automated Application

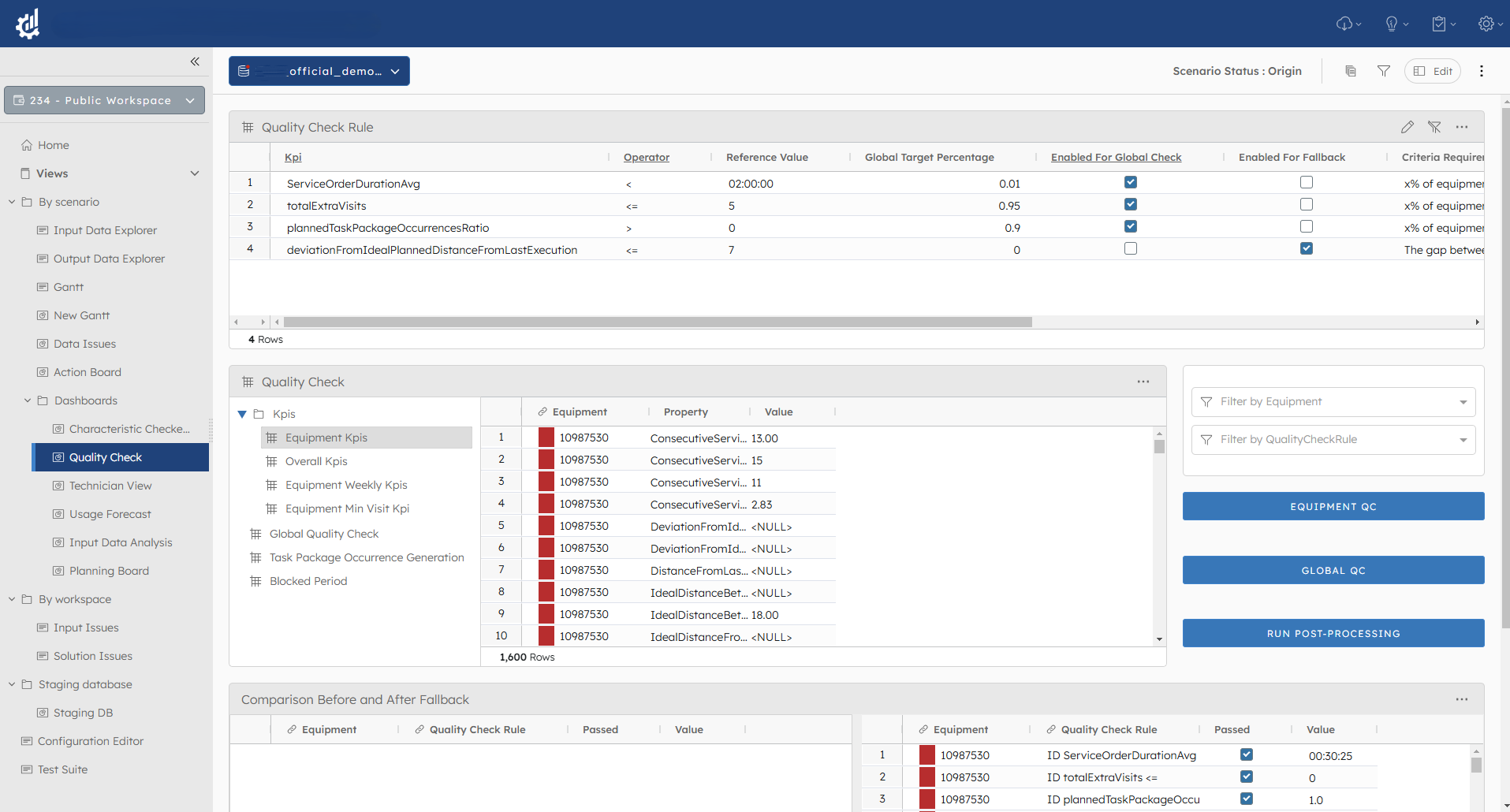

Addressing these challenges required a comprehensive solution that could dynamically adjust maintenance schedules based on real-time data, enable advanced maintenance practices such as task-specific and condition-based planning, and streamline global processes. The goal was to create a fully automatic and efficient planning system that would reduce complexity, improve resource utilization, and deliver consistent performance across all regions.

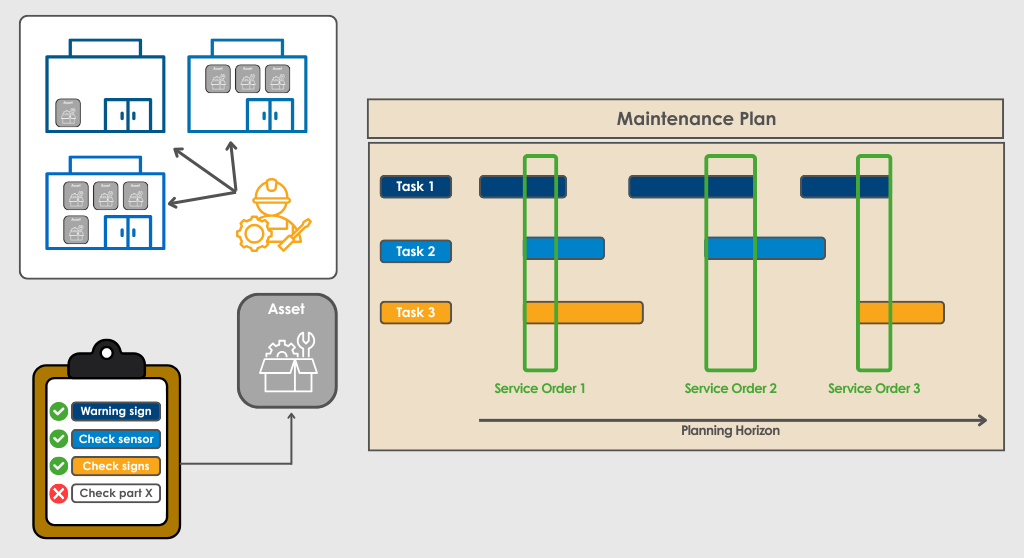

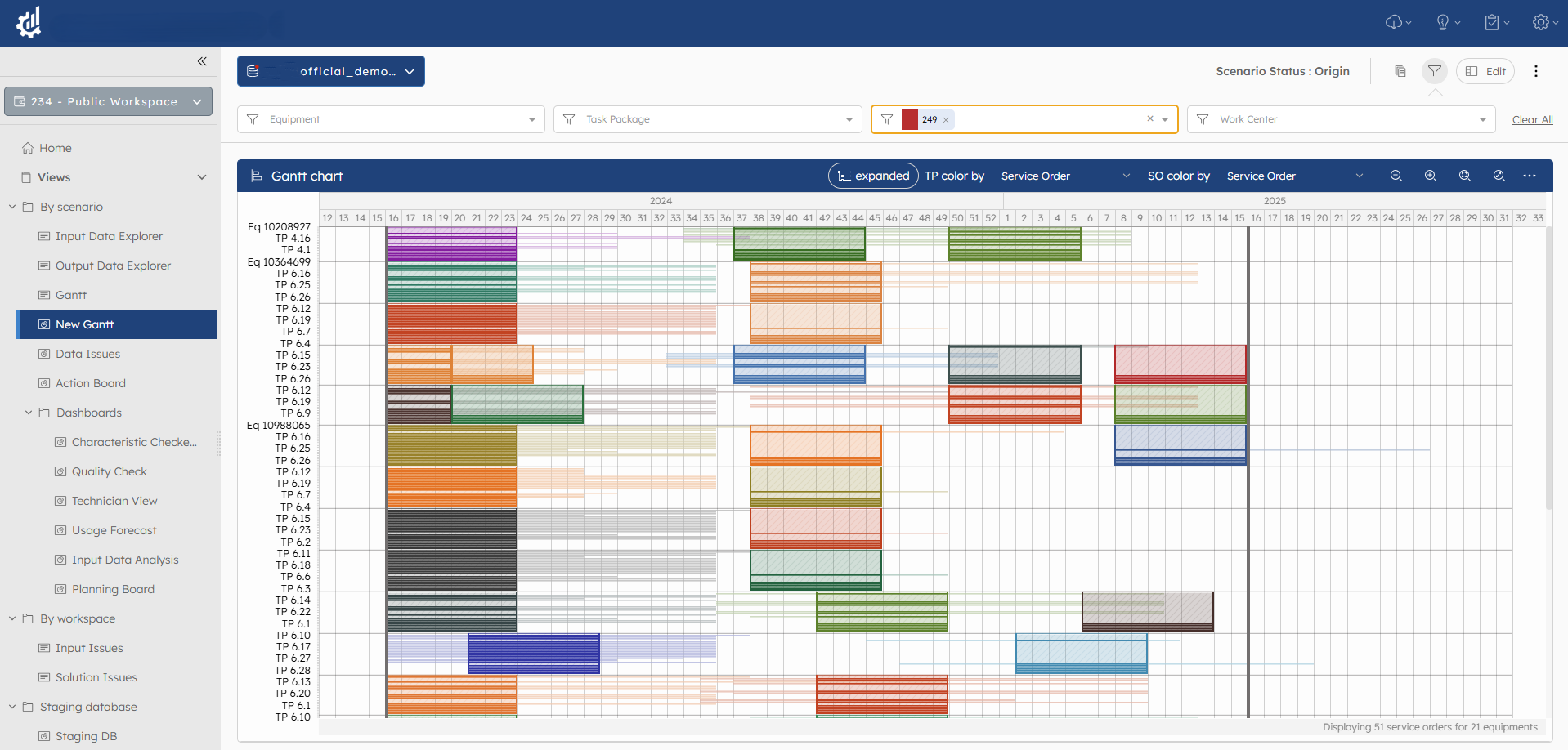

To achieve this, the company and DecisionBrain implemented an automated maintenance planning tool that is trained on the real usage of each asset. It is a fully automated application that dynamically customizes and optimizes the maintenance plan for each piece of equipment on a weekly basis over the course of a year. It considers specific usage patterns, IoT signals, contract SLAs, and safety procedures to tailor an ideal maintenance strategy for a diverse pool of geographically distributed assets. This ensures each asset is optimally maintained while minimizing downtime. The solution creates:

- Predictive maintenance plans dynamically optimized based on the characteristics of each asset

- Task schedules that ensure tasks are performed at the right time using equipment usage forecasts

- Optimized maintenance visits by optimally bundling multiple tasks into a single visit

- A fully automated system requiring minimal manual intervention, including configurable quality checks and fallback strategies

- A scalable and sustainable design that can accommodate increasing capacity and support global rollout across multiple countries

- Calculation of spare parts needs, reducing the risk of out-of-stock situations

Results

Delivering Efficient, Flexible and Scalable Maintenance Success

The solution has been deployed in 16 countries, with over 200,000 assets currently utilizing the system. By implementing our advanced maintenance planning tool, the company successfully transitioned to a modern, efficient maintenance approach. This collaboration not only optimized operational processes but also demonstrated DecisionBrain’s ability to deliver scalable, high-quality solutions that drive measurable business value. The collaboration between the company and DecisionBrain delivered significant improvements:

- Operational Efficiency: The number of unnecessary maintenance visits was significantly reduced, and technicians could maintain multiple pieces of equipment in a single visit, minimizing travel time, and asset downtime.

- Improved Flexibility: Maintenance schedules shifted from static to dynamic, enabling adjustments based on operating conditions.

- IoT Integration: IoT data can be effectively used with the AI / optimization models, improving planning and execution.

- Robustness and Scalability: The solution was built for long-term sustainability, emphasizing robustness, scalability, and the ability to handle increased capacity as adoption grew. This structured approach ensured that the system not only addressed immediate operational needs but also aligned with the company’s long-term business objectives.

Want to learn more? Discover how our maintenance optimization solutions can help your business thrive.