Solution

Manufacturing

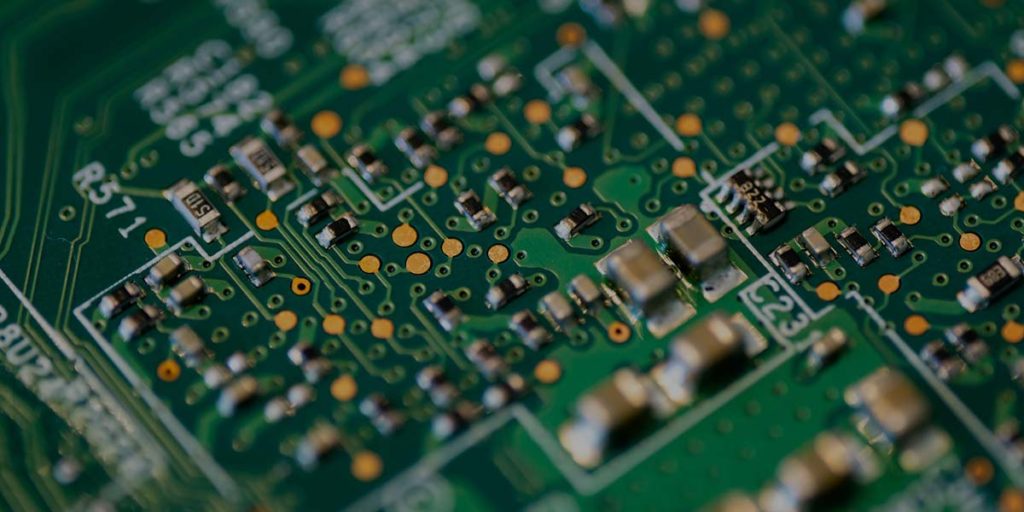

Production Planning for Semiconductors

Overview

Working with a leading semiconductor wafer manufacturer to optimize its plant in Canada.

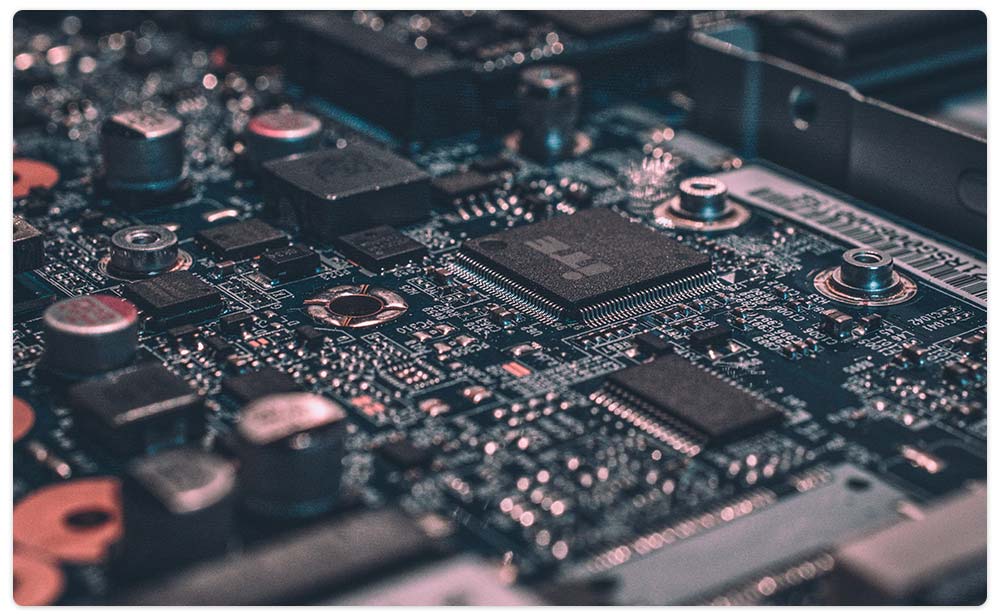

The semiconductor plant located in Bromont (Canada) specializes in the assembly and testing of semiconductors. The production process starts from the 300mm wafer that contains several chips and ends with assembled and tested modules.

Before the project with DecisionBrain, the client used a packaged software that provided basic capacity planning functionalities, without embedding any optimization. The software struggled to cope with new demand formats received from customers.

A high proportion of Part Numbers (PNs) are produced on small production runs. Approximately 20% of PNs have long production runs, while the rest have short runs. The process has a high variability coming from:

- High demand variability

- High supply variability (wafers quantity/product mix)

- High process variability (e.g. different PNs are created as a result of testing)

All these factors, combined with a complex production process, make planning particularly difficult. Manual planning is far from optimal, especially considering that demand could change from one day to the next.

They were looking for a reliable customized long-term planning solution that could cope with all these issues.

Solution

A long-term plan with successful on-going results.

In order to provide a new long-term planning tool to the plant, an optimization-based solution was implemented.

The tool engine is based on a planning model that takes into consideration the specific demand and manufacturing processes. A custom workload balancing objective function has been implemented in order to improve the operators hiring efficiency.

Several performance indicators were considered in order to find the best long-term plan:

- Maximize revenue

- Minimize tardiness

- Minimize production costs

- Maximize workload balancing

A weighted sum approach combined with hierarchical optimization has been used to find the best combination of performance indicators.

The long-term plan is run at least once a week. Using the automatically generated custom reports, the planner can easily assess the solution quality and adjust it if needed.

Overall this project has been very helpful for the plants and planners alike. The project continues to produce strong results as DecisionBrain works to further improve the solution.