Whether you’re moving freight on land, air, or sea, within a city, or around the world, sometimes your needs go beyond what’s possible through your manual processes, legacy planning, scheduling & routing tools, or even your ERP, TMS, or execution system.

Software that Empowers Efficient and Resilient Logistics Plans

Modular Planning & Scheduling Optimization Software

Increase efficiency by 10%. Reduce planning time by 90%. Realize ROI in under a year.

DB Gene by DecisionBrain is a modular logistics planning and scheduling platform that provides ~80% of needed functionality for most logistics planning and optimization use cases out-of-the-box – even for the most complex or unique use cases. The remaining ~20% of customer-specific requirements typically take 3-7 months to configure and deploy.

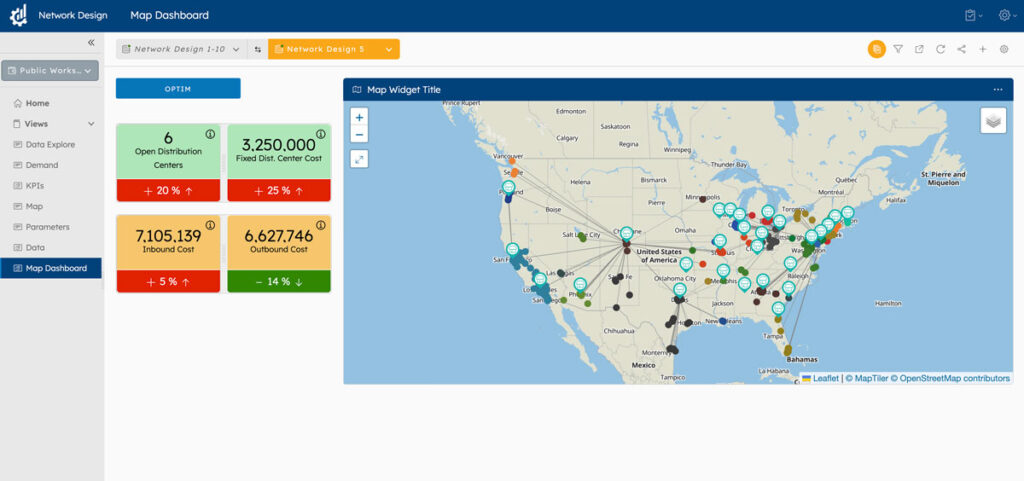

Solutions by Time Horizon

Planning on an annual, quarterly, monthly or weekly basis

Plan and adjust your supply chain and logistics network by optimizing warehouse and fulfillment center locations, plant capacities, modes of transport, supplier selection, inventory targets and workforce configuration.

Planning on a quarterly or monthly basis

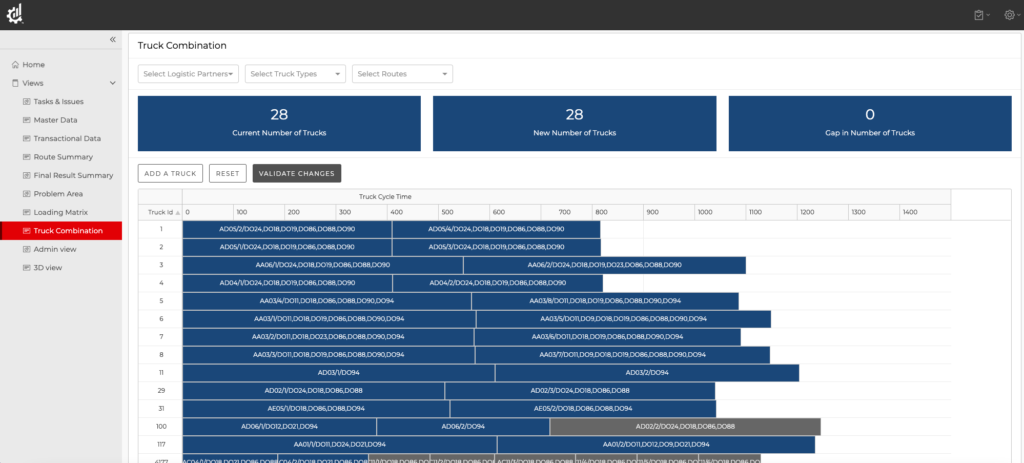

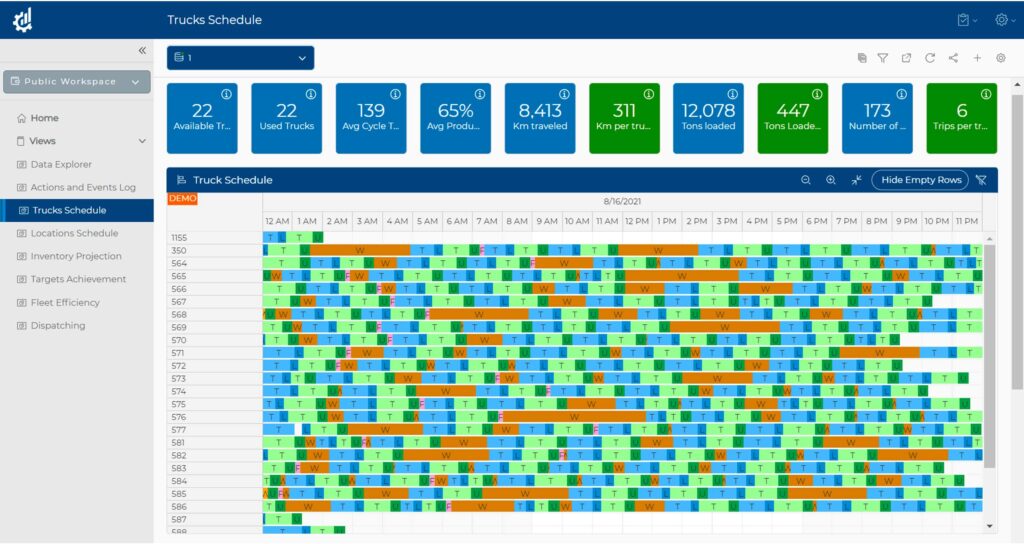

Create detailed daily plans that satisfy all work demand by:

- creating detailed demand forecasts

- assigning loads to vehicles or contractors, including splitting loads through the day to support just-in-time deliveries

- optimizing stop orders and routes

- creating 3-D container/trailer/vessel load plans

- route your vehicles

- smoothing the workload throughout the day, week, month and year to minimize workload peaks that require contractors or overtime.

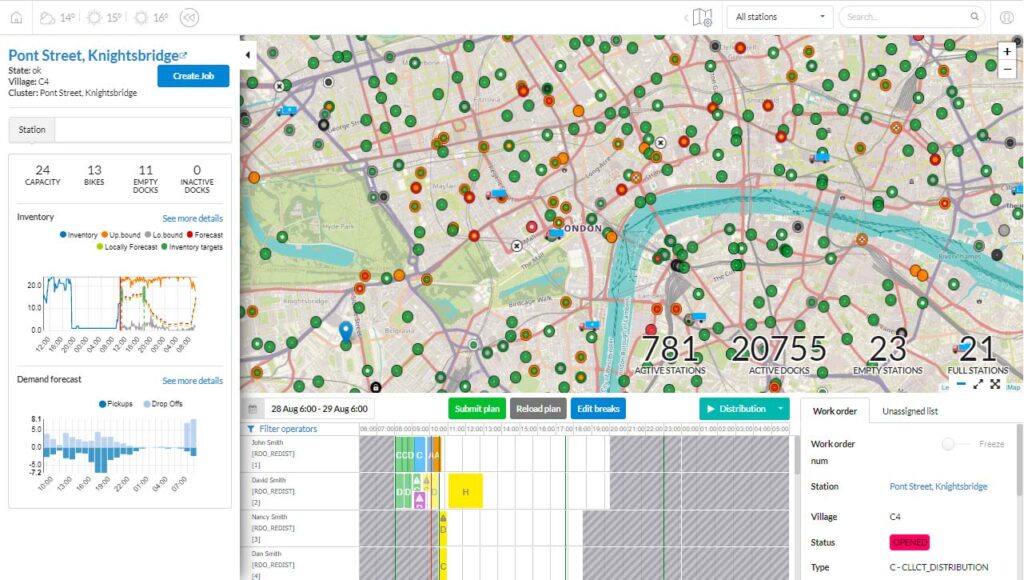

Planning on a weekly, daily or real-time basis

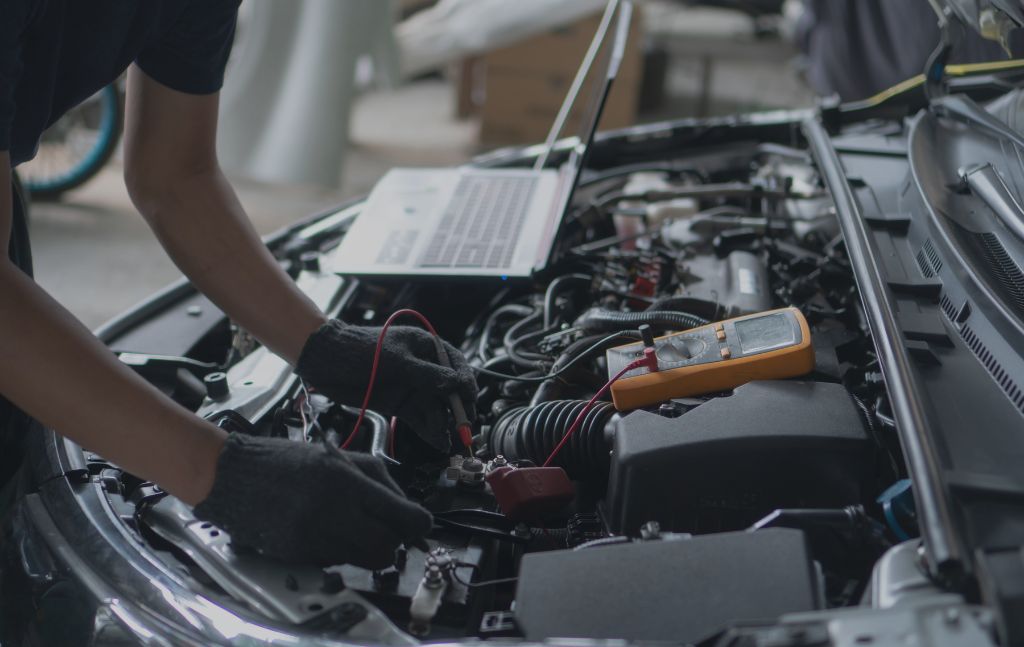

Our workforce and maintenance optimization solutions cover strategic planning, tactical planning, operational scheduling and real-time dispatching.

Who is it for?

Ideal for owned or managed fleets and unique or complex requirements

- Departmental silos that make load consolidation challenging

- Unexpected situations (weather, breakdowns, staffing, etc) that require adjustments that could have ripple effects on the schedule

- Assigning orders to routes and/or routes to resources

- Orders that must be split into multiple loads (order balancing) in order to optimize supply/demand matching, reduce inventory congestion or achieve just-in-time delivery to the production facility

- Reverse logistics requirements to support re-use of pallets, containers or other packaging

- 3-Dimensional loading instruction, considering factors like load/pallet dimensions, stacking rules, orientation, weight balancing, LIFO or grouping considerations

Different vehicle/vessel/aircraft types that limit load types, dock/port/terminal locations, etc. - Limited freight load/unload windows at docks/ports/terminals

- Workforce preferences, objectives and constraints need to be considered (hours, teaming, overtime, etc)