Overview

Demanding Customers that require high Service Level

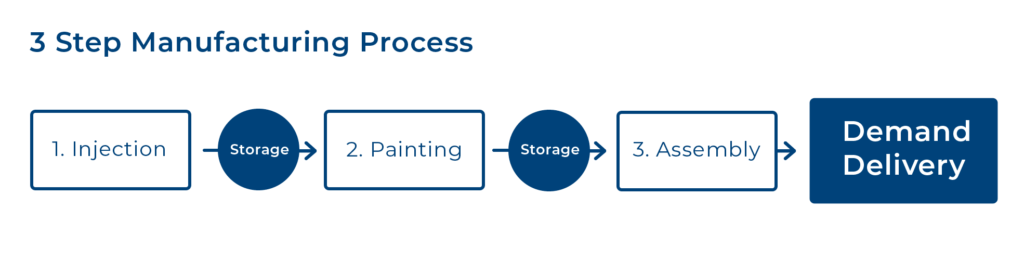

An automotive supplier that produces pre-assembled auto parts and delivers them to the assembly line of the car manufacturers.

Providing high customer service is a key factor for the company’s success: it must produce under a mix of Make-to-Order and Just-In-Time for its automotive customers. With demands that should be satisfied within 5 hours, it is essential to have enough stock of semi-finished products (painted parts) and be able to react very quickly. This translates into a schedule of the paint line that gives the right priority to each product.

Solution

Smart Scheduling to improve efficiency and service level

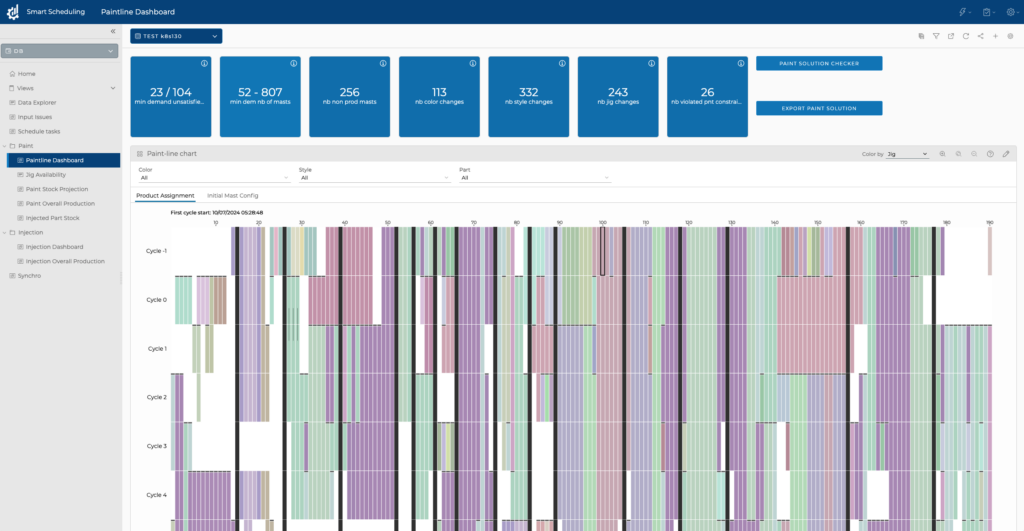

The company needed to enhance its scheduling capabilities. The Smart Scheduling initiative is part of a broader Industry 4.0 effort. Its main focus is developing optimal scheduling for the painting line, fully integrated with the injection line.

Beside improving production efficiency and service level, the initiative aims at reducing the time required to develop operational schedules, so that planners can generate better quality plans.

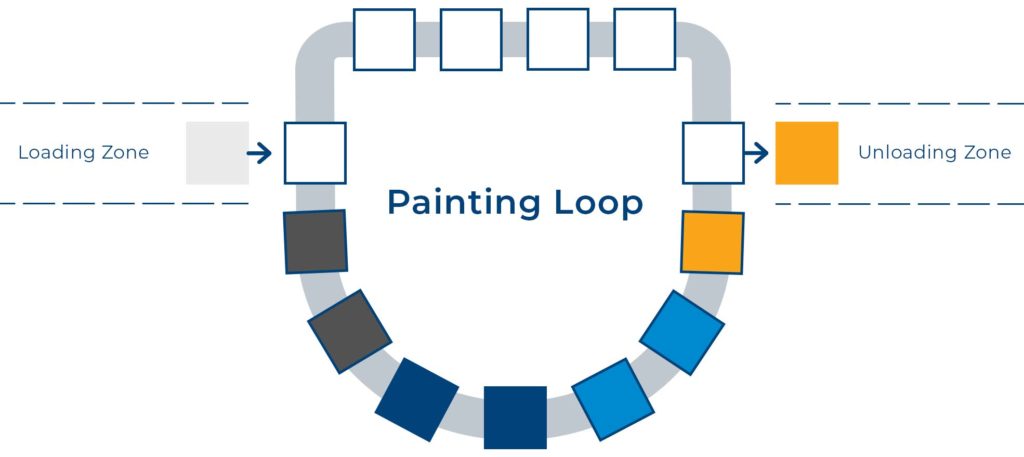

Painting loop description

The solution develops an optimal integrated scheduling between the injection and the paint lines to improve on key operational KPIs:

- Maximize Service level by respecting target production quantity before due date

- Minimize color changes and paint loss

- Minimize number of empty masts

Example of Paint line interactive Gantt chart scheduling.

Results

48% improvement in the service level and 67% in capacity usage

The pilot implementation delivered strong results along all these operational KPIs with a running time below two hours. Different scenarios were made by changing constraints and demands, and all delivered satisfactory results, such as 48% improvement in the service level and 67% in capacity usage. The solution allows planners to adjust the schedule depending on the KPI that needs to be optimized.