Solution

Planning and Scheduling

Workforce Optimization for an Agriculture Cooperative Group's Grain Storage and Logistics Services

Summary

Challenge

A French agricultural cooperative group faced challenges in optimizing its workforce for its grain storage and logistics services. Their highly variable and seasonal work demand pattern was difficult to efficiently satisfy with a primarily stable workforce. Sometimes employees were idle while at other times, the company incurred extremely high expenditures on temporary labor to handle the periods of high demand. Data access and visibility challenges also hampered efforts toward efficiently planning and scheduling their workforce.

Solution

DecisionBrain delivered a custom-fit Workforce Planning and Scheduling Optimization system that improved demand anticipation, better-aligned workforce capacity with demand patterns, and ensured that HR regulations were being adhered to. The system leverages a powerful mathematical optimization solver to present planners with recommended workforce plans that achieve consistently good outcomes across various key performance indicators tied to service level, cost, employee satisfaction, and efficiency metrics.

Results

- Empowered the Agricultural Cooperative Group to make more informed and timely decisions based on accurate and current data

- Increased productivity by better matching workforce capacity to work demand

Overview

How Matching Workforce Planning for Grain Storage and Logistics Services with Demand Became a Challenge

A French agricultural cooperative group that provides crop inputs, grain storage and logistics services, animal feed, and agricultural equipment to its members and customers. One of its key divisions provides grain storage and logistics services across 220-grain silos and storage facilities throughout France.

This division faced a challenge in correctly staffing its workforce to meet fluctuating and seasonal work demands at its different facilities. Frequently, certain facilities were either overstaffed or understaffed, leading to inefficiencies and delivery delays.

One contributing factor was data availability and visibility. Workforce planning was conducted by division managers who individually gathered silo fill and workforce capacity information in an ad-hoc manner, both through manual inspection at sites and from disparate systems. One such system, for example, uses satellite imagery of croplands to help forecast harvests.

Another factor that made workforce planning hard was the difficulty in scheduling a primarily steadily-employed workforce to a highly variable, seasonal and multi-faceted work demand pattern. The workforce is geographically distributed and possesses a mix of skills and certifications that must be properly matched to the work demand, which includes loading and unloading of grain, handling of pesticides, cleaning of silos, and grain quality testing and grading to ensure shipments are compliant with sales and export standards.

These and other factors contribute to the difficulty in creating workforce plans and weekly schedules that consistently meet demand and reduce employee idle time as well as stress from being overworked.

Solution

Agriculture Workforce Planning and Schedule Optimization

To overcome the challenges of demand visibility and workforce optimization, the company partnered with DecisionBrain to implement a comprehensive Workforce Planning Optimization system.

The first part of the solution focused on enhancing demand anticipation through standardized methods and process changes. This included tracking current grain inventory levels and using machine learning-powered forecasting tools that utilized data from weather and satellite imagery. By combining location-level inventory data with the output of these forecasting tools, the company could better anticipate work demand by day, week, activity, and location (silo).

The system also integrated employee location, skills, travel, and working hour restrictions data from HR and other systems, allowing workforce capacity to be better aligned with demand while complying with HR rules and also considering employee preferences. This produced a more accurate and complete picture of work demand and workforce capacity, enabling planners to better collaborate and make more informed decisions.

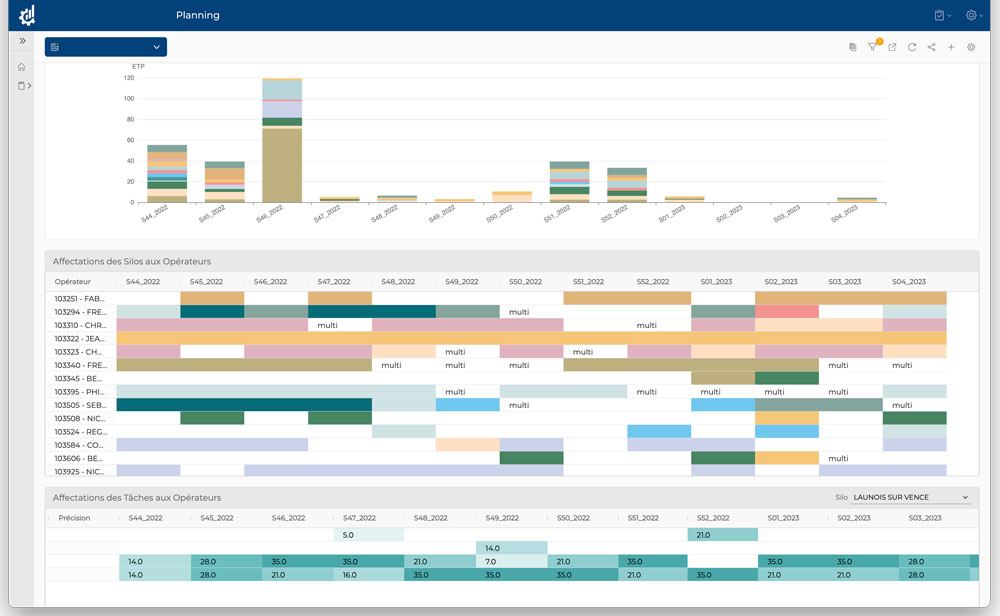

Now that the data is integrated into the Workforce Planning Optimization system, it is regularly processed by the system’s mathematical optimization solver, which is the “brain” of the system. This solver quickly assesses millions of possible plans and presents planners with recommended workforce assignments and schedules that achieve the best outcome in terms of the business’s key performance indicators (KPIs), such as employee idle time, contractor costs, customer delivery time, and service level. If needed, planners can manually adjust parameters or make manual adjustments to plans and then compare scenario results visually and through KPIs.

Results

Achieving Cost Reductions for Grain Storage and Logistics Services

Thanks to the Workforce Planning Optimization system from DecisionBrain, the company has been able to significantly reduce its operating costs for grain storage and logistics services by optimizing workforce assignments to silos, minimizing contractor utilization and reducing the need for costly grain treatment due to better inventory management. In addition to these cost savings, the solution has empowered the Agriculture Cooperative Group to make more informed decisions backed by clear and convincing data. This enables the company to justify additional resource investments and confidently defend its recommendations or decisions.

Want to know more?

Read more about workforce optimization in our Guide to Workforce Optimization whitepaper, or speak with an expert!