Blog

Part 4: Operational Scheduling – The Complete Guide To Workforce Optimization

Our last two articles in this series outlined how to:

- 1. Create a

catalog of employee skills and work task types

so that we have a common language with which to talk about workforce capacity and work demand

- 2.

Benchmark activity performance

rates for the various task types so that we can determine how much workforce capacity is needed to fulfill a given amount of work.

- 3. Handle uncertainty with forecasting and capacity planning as inputs for our workforce optimization activities.

Now we’re finally able to begin reaping the benefits of all of this foundational work and start optimizing!

We will begin with operational scheduling optimization in this post before moving on to tactical and strategic planning, which will be the subjects of our next blog posts.

Why start with Scheduling instead of Planning Optimization?

We are beginning the optimization topic with operational scheduling rather than strategic or tactical planning optimization because it’s where, for many of our customers, the day-to-day “pain” is most apparent and urgent.

While we have supported clients in addressing optimization opportunities along the three planning horizons (strategic, tactical, operational) in different orders, a best practice would be to tackle strategic planning first, followed by tactical planning and then operational scheduling.

The reason for recommending strategic and tactical planning optimization first is because they usually deliver the greatest ROI: the benefits of good strategic decisions, such as hiring the right workforce, can have the biggest impact on the business KPIs, whereas even the best operational scheduling system in the world can’t entirely fix, say, a shortage of workers with the right skill sets or improper distribution of the skills across a region.

The tradeoff, however, is that the ROI for planning optimization takes the longest to realize because one must wait for the next planning period (typically a year or more out) to be well underway before the impact can be felt. In contrast, operational scheduling optimization’s benefits begin accruing within days or weeks of implementation.

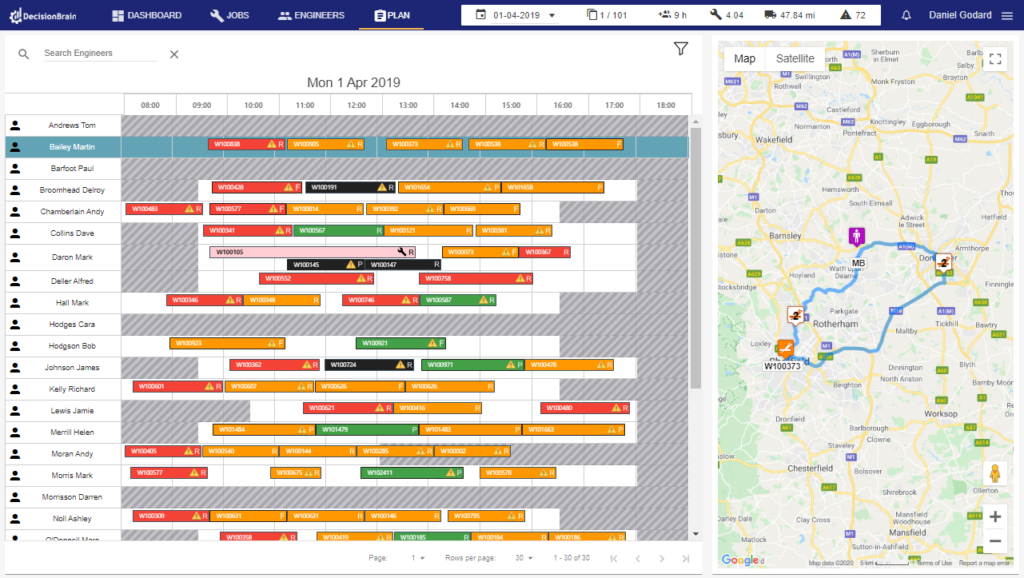

Figure 1: Technician Scheduling Dashboard

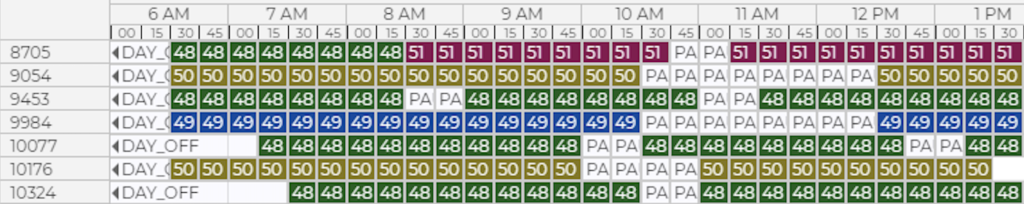

Figure 2: Contact Center Agent Scheduling Chart

Operational Scheduling Challenges

Workforce scheduling isn’t always hard, but for most organizations with hundreds or more employees, it can get surprisingly complex very quickly. Here are some contributors to scheduling complexity:

- A workforce made up of people with different skills, which must be matched to different kinds of work demand. This could apply in a call center or field services, for instance.

- Staff are geographically distributed, so proximity and route to work location must be considered.

- The work is a mix of regular recurring and reactive jobs, common with technicians or emergency responders.

- Last-minute situations, such as employee absences or rush jobs require adjustments that can have ripple effects on the schedule.

- Allowable visits or work windows may be tight or vary, such as with medical sales reps who visit doctors during their opening hours.

- Availability of scarce or shared equipment must also be considered in the schedule, such as construction or hospital equipment.

- Customer or work priorities and service level agreements vary.

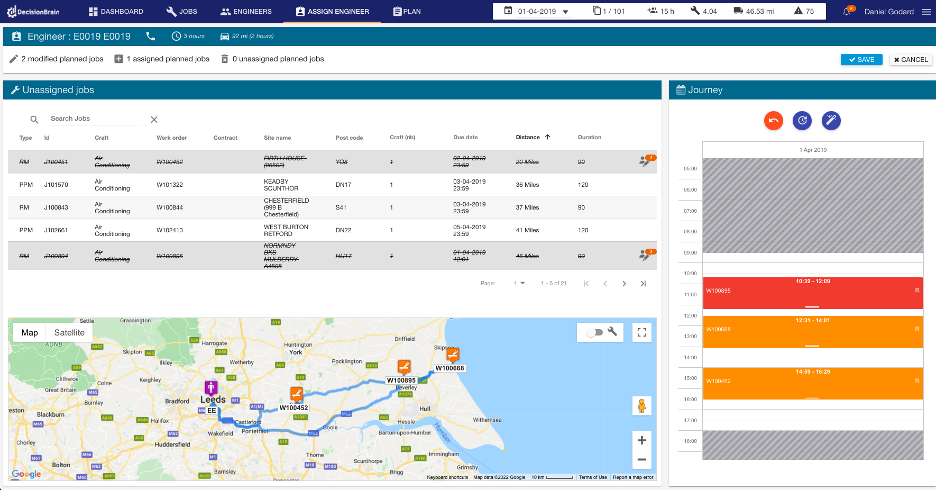

Figure 3: Unassigned Job Handling Screen for Schedule Repair

Workforce Scheduling, Rostering, Field Service Management and Shift Management Software

Most organizations find it impossible to manually create consistently good schedules when faced with the challenges above, especially when trying to balance across competing objectives, like minimizing costs, maximizing customer service levels and satisfying employee preferences.

This is why organizations often use software to help with scheduling. But what kind of software is appropriate?

There are many types of software systems that claim to facilitate, automate and even “optimize” employee scheduling. They include:

- Rostering systems

- Workforce Management (WFM) systems

- Shift Management Software

- Employee/Workforce Scheduling Software

- Field Service Management (FSM) systems

- Customer Relationship Management (CRM) systems.

An internet search will produce endless “top 10” lists and reviews of the various systems. The differences are usually based on the “accessory” functions of the systems, which are outside of scheduling optimization. That is because most of these systems are touted as “one-stop shops” for all of your workforce management needs rather than being focused on operational scheduling optimization. That’s not to say they aren’t good systems – they include very important features like time and attendance management, GPS location tracking, mobile interfaces, shift bidding, integration with financial, asset management and/or CRM systems and other such management and execution functionality.

The limitation of nearly all of these systems is that the scheduling functionality is too simplistics. The scheduling functionality is either manual (calendaring) or, if automated, is extremely limited in the number of factors that can be considered when producing the schedule. This is due to the exponentially increasing number of schedule possibilities (and therefore, problem complexity) that results when you want to consider several factors.

Let’s take, for instance, just one of the factors listed above, which is that of a geographically distributed workforce. Let’s say you have a team of field technicians who must travel to different work locations. Look at how quickly the problem blows up:

Figure 4: Optimization Problem Complexity

Add to this the need for interactivity and schedule shuffling. In the real world, jobs run late, workers don’t show up and other such daily “fires” need constant tending. A scheduling system must enable the planner to make frequent changes, freeze parts of the schedule and re-plan other parts, either by hand or with a local re-optimization. This often requires some serious computer processing and algorithmic horsepower to do well.

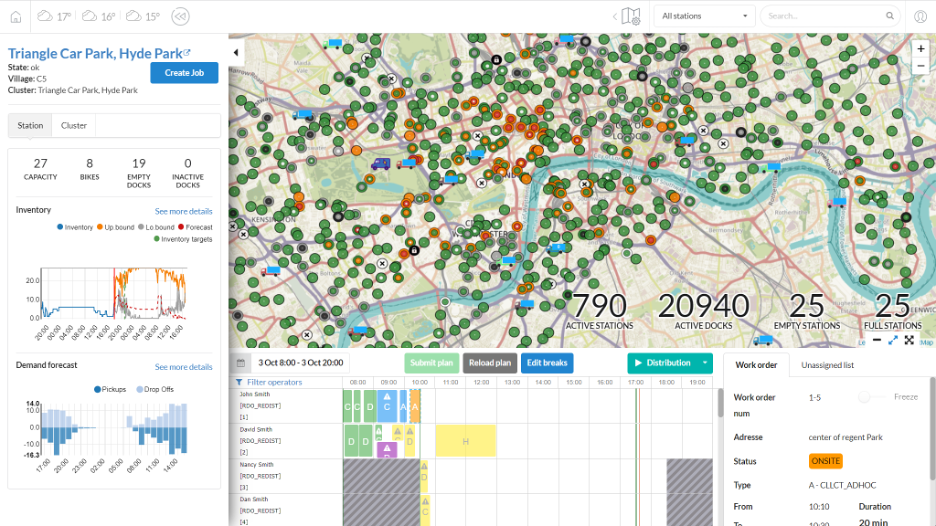

Figure 5: Route Optimization Dashboard

How to Achieve True Workforce Schedule Optimization

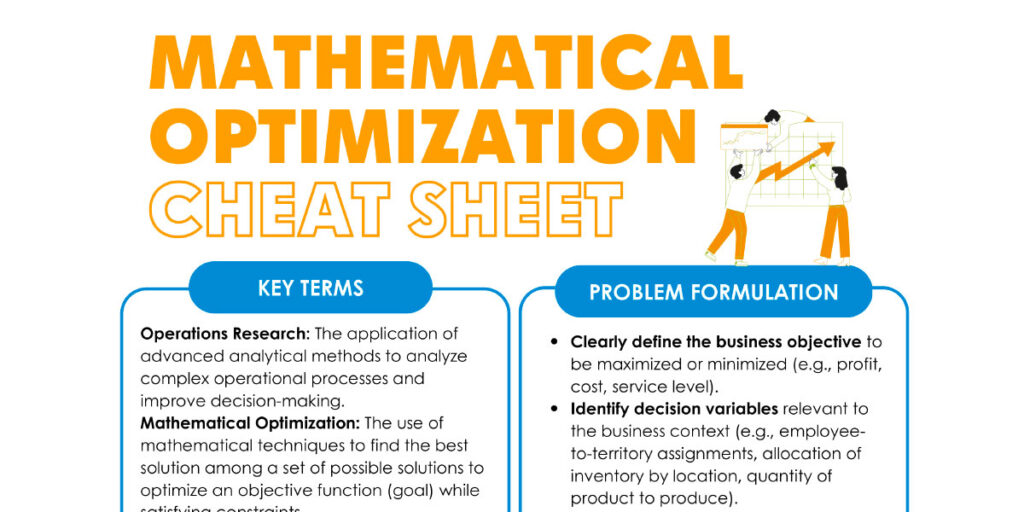

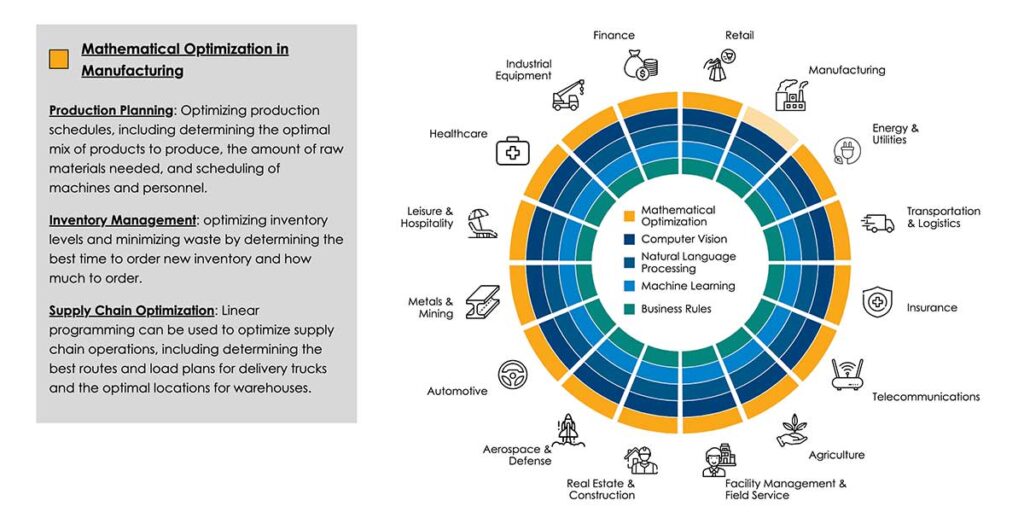

The industry “gold standard” for solving hard workforce scheduling problems is to leverage mathematical optimization tools. Airline crew scheduling applications, for instance, have for many years embedded such tools. Unfortunately, the vast majority of the scheduling software for most other industries and use cases is quite limited in optimization functionality.

Here are some important features to consider when looking for a workforce scheduling optimization system:

- Demand planning & forecasting – so that you know how much of what types of work demand you’ll have to satisfy with your schedule.

- Resource management – the ability to manage or at least integrate a detailed catalog of workers, skills, roles, availability, etc.

- Manual schedule adjustment – to enable the user to make manual adjustments to the schedule if necessary.

- “Repair” the schedule – to allow the user to perform a “local” repair, or re-optimization with minimal disruption to the overall schedule, in case unexpected events occur during the day.

- KPI management – to track metrics like labor cost, resource utilization, overtime cost/hours, late jobs, service level, over and understaffing, late jobs, etc.

- Executive dashboards – preferably supports integration with other analytics & BI tools and allows easy export of all data.

- Role-based workspaces – so that users can access the appropriate data and functionality for their role.

- Mathematical optimization engine – inclusion of a reputable optimization “solver” or engine embedded in the tool. Simply ask, “Which optimization solver do you embed in your solution?”. The vendor should respond with something like IBM CPLEX or Gurobi. If they talk about “rules” and “heuristics” or don’t elaborate on the solvers that they embed, just know that the level of “optimization” and the flexibility in the factors that the system can consider will be quite limited.

- On-demand, batched and regular schedule generation – the ability to create an optimized schedule at the push of a button, as part of a (nightly) batch process, or on a regular (e.g. hourly) scheduled basis.

- Ability to also support tactical and strategic planning – the best input to an operational schedule optimizer is a good tactical plan for the month. Similarly, the best input to a tactical plan optimizer is a good strategic plan. To achieve true global optimization, integration between these 3 functions is key. More about this in the next two blog posts.

- Ease of integration with external systems – scheduling optimization could be considered as an “intelligent” add-on module that sits on top of existing legacy systems (e.g. CRMs[Customer Relationship Management], CAFMs [Computer Aided Facilities Management], ERPs [Enterprise Resource Planning], or HR [Human Resources] systems, …). In this case, the operational scheduling system must be easy to integrate with or at least exchange information with these systems.

Figure 5: Route Optimization Dashboard

What if No System Meets My Exact Needs?

Scheduling problems are known to be harder to solve by off-the-shelf software applications, which is why many scheduling systems used by larger organizations are custom-developed, either as standalone systems or as bolt-ons to extend the functionality of other HR, FSM or CRM systems.

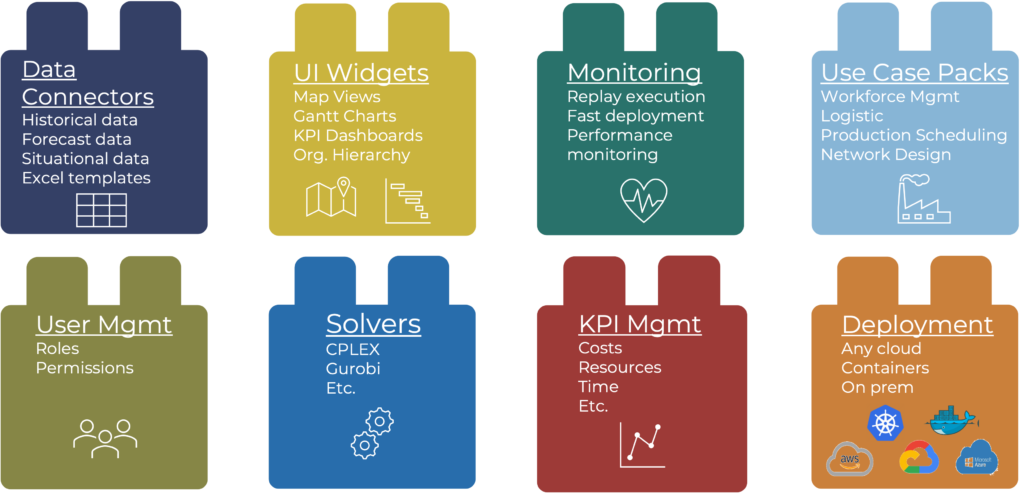

A hybrid approach does exist, and that is to leverage an application development platform – ideally one that is purpose-built for optimization (or operational planning or scheduling) use cases, such as DB Gene by DecisionBrain and Decision Optimization Center (DOC) by IBM.

Figure 7: DB Gene Platform Components

We at DecisionBrain use our DB Gene platform to deliver fully custom scheduling applications to our customers, typically in 3-7 months. That is thanks to DB Gene providing ~80% of the functionality needed for workforce scheduling optimization out of the box.

Other articles in The Complete Guide to Workforce Optimization:

Introduction to our Series

Part 1 Cataloging Employee Skills and Work Activities

Part 2 Benchmarking Performance Metrics

Part 3: Handling Uncertainty with Forecasting and Capacity Planning

Part 5 Tactical Planning

Part 6 Strategic Planning

About the Author

Anna Bassi is a Sr. Business Analyst with DecisionBrain. She brings extensive experience delivering advanced planning and scheduling, manufacturing and workforce optimization solutions to organizations with large or distributed plants and teams. She holds a master’s degree in Mathematics from the University of Padua in Italy.