Blog

Mathematical Optimization Cheat Sheet

Welcome to the world of Mathematical Optimization!

This Cheat Sheet functions as your guide to grasp fundamental concepts associated with mathematical optimization.

Key terms:

- Operations Research: The application of advanced analytical methods to analyze complex operational processes and improve decision-making.

- Mathematical Optimization: The use of mathematical techniques to find the best solution among a set of possible solutions to optimize an objective function (goal) while satisfying constraints.

- Mathematical Optimization Model: A representation of an optimization problem consisting of variables, an objective function to be maximized or minimized and a set of constraints that limit the universe of possible solutions.

- Prescriptive Analytics: The use of mathematical models, optimization algorithms, and data analysis to provide recommended actions and decision strategies that optimize business outcomes based on specific objectives and constraints.

- Optimization Engine/Solver: A software component or system that utilizes algorithms and mathematical techniques to solve optimization problems.

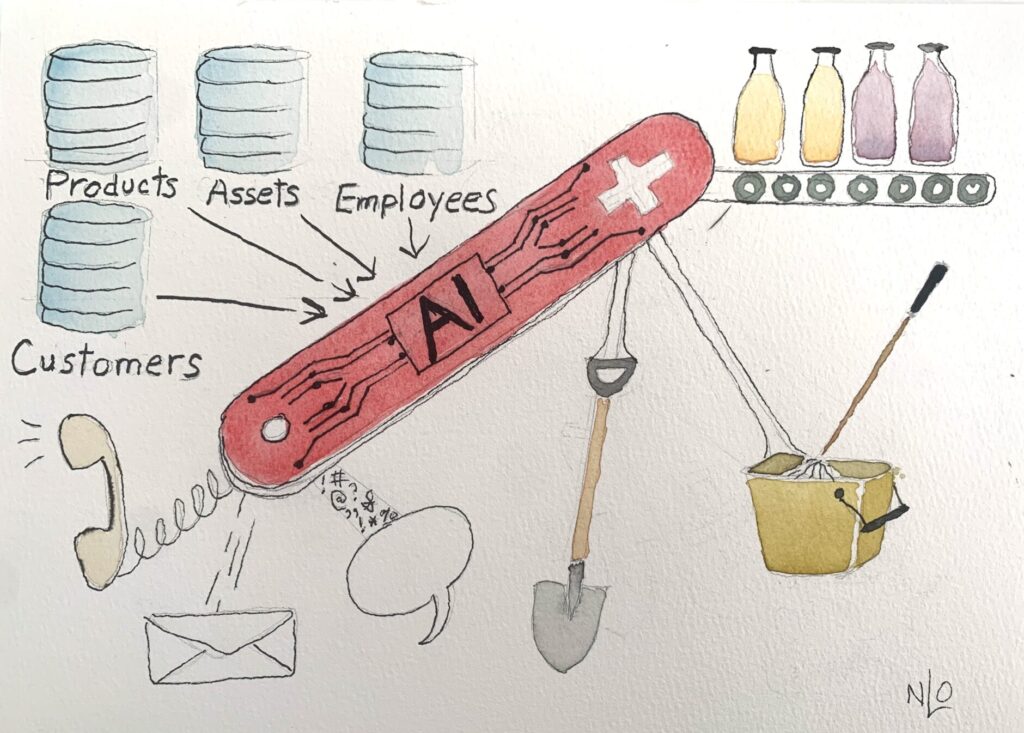

Top 10 industrial use cases:

- Production Planning and Scheduling: Optimizing production levels, scheduling manufacturing processes, and coordinating resource allocation to maximize production throughput and capacity utilization and minimize costs and waste.

- Routing and Logistics Optimization: Optimizing routes for transportation and delivery, vehicle routing, and fleet management to reduce fuel consumption, improve delivery times, and minimize overall costs.

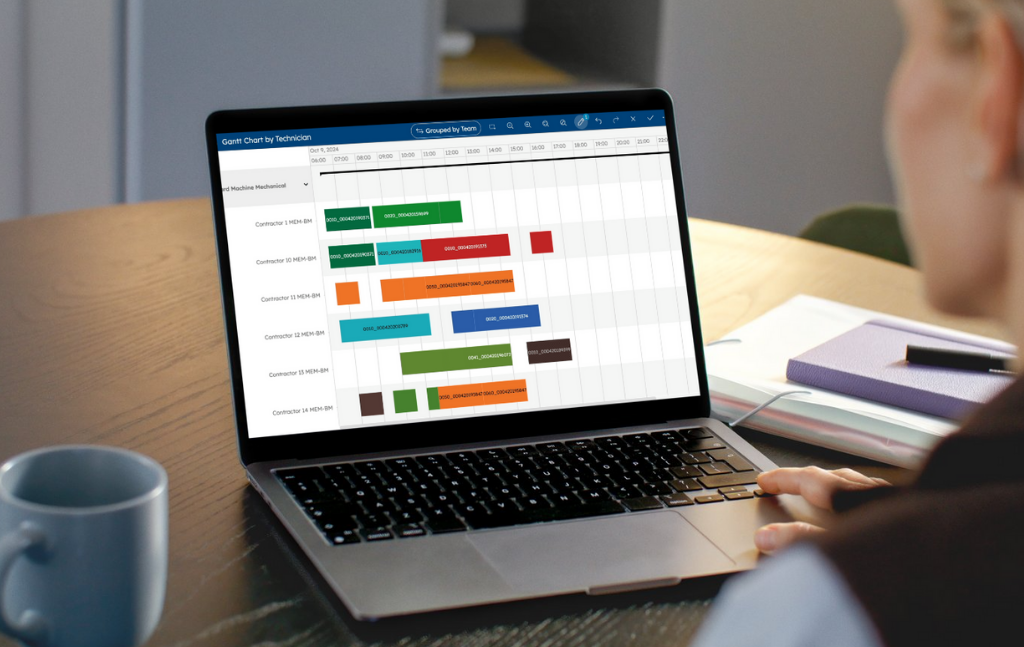

- Workforce Optimization: Optimizing the team structure, client/activity assignment and scheduling of employees, and especially those who work in the field and must travel to job assignments but also commonly used in call centers, healthcare and manufacturing, where efficient workforce scheduling is crucial to maintain productivity and employee satisfaction.

- Strategic Network Design: Determining the optimal locations for facilities such as production facilities, warehouses, fulfillment centers, or retail outlets, considering factors like customer demand, transportation costs, and market coverage.

- Inventory Optimization: Determining optimal inventory levels, reorder points, and replenishment strategies to balance costs and customer service levels.

- Maintenance and Asset Optimization: Optimizing the planning and scheduling of planned and preventative maintenance activities, the allocation of resources and parts replacement strategies to maximize equipment uptime, minimize maintenance costs, and extend asset lifespans.

- Space Planning: Finding the best layout or allocation of available space to achieve specific objectives, often used in retail for placement of goods on shelves, real estate for occupancy space planning in residential or office spaces, and warehouses in order to facilitate streamlined storage, retrieval and movement of goods.

- Portfolio Optimization: Optimizing investment portfolios to maximize returns while managing risk by selecting the best combination of assets based on their expected returns, volatility, and correlation

- Revenue & Yield Management: Pricing strategies that optimize the allocation of limited resources or inventory, such as airline seats or hotel rooms, to maximize revenue and profitability.

- Assortment Optimization: Determining the best combination of products or services to offer in a given retail store or portfolio, aiming to maximize sales and profitability while meeting customer demand and preferences.

Problem Formulation:

- Clearly define the business objective to be maximized or minimized (e.g., profit, cost, service level).

- Identify decision variables relevant to the business context (e.g., employee-to-territory assignments, allocation of inventory by location, quantity of product to produce).

- Specify constraints (eg limitations on resources like space, labor, materials, or equipment)

Performance Evaluation:

- Measure the business performance metrics affected by the optimization solution (e.g., profit, cost savings, customer satisfaction).

- Conduct scenario analysis to evaluate the solution’s performance under different business conditions.

- Monitor key performance indicators (KPIs) to ensure sustained benefits and make adjustments if necessary.

Software Tools:

- Mathematical Optimization Solvers:

- Industrial solvers: CPLEX, Gurobi, FICO XPRESS, Hexaly

- Open-source solvers: SCIP, GLPK, OR-tools

- Modeling Languages: Use algebraic modeling languages (AMPL, GAMS) to describe optimization problems concisely.

- Programming Languages: Utilize optimization libraries in languages like Python, Java, or MATLAB (Optimization Toolbox).

- Optimization Development Platforms: For turning your models into full applications. Like DB Gene, IBM DOC.

DecisionBrain is a leading provider of advanced decision support software that is used to solve the world’s hardest supply chain, workforce and maintenance planning, scheduling & logistics optimization problems. With over 400 person-years of experience in machine learning, operations research and mathematical optimization, DecisionBrain delivers custom-fit decision support systems where packaged applications fall short. Read more about us or contact us to talk about our solutions!

Read also