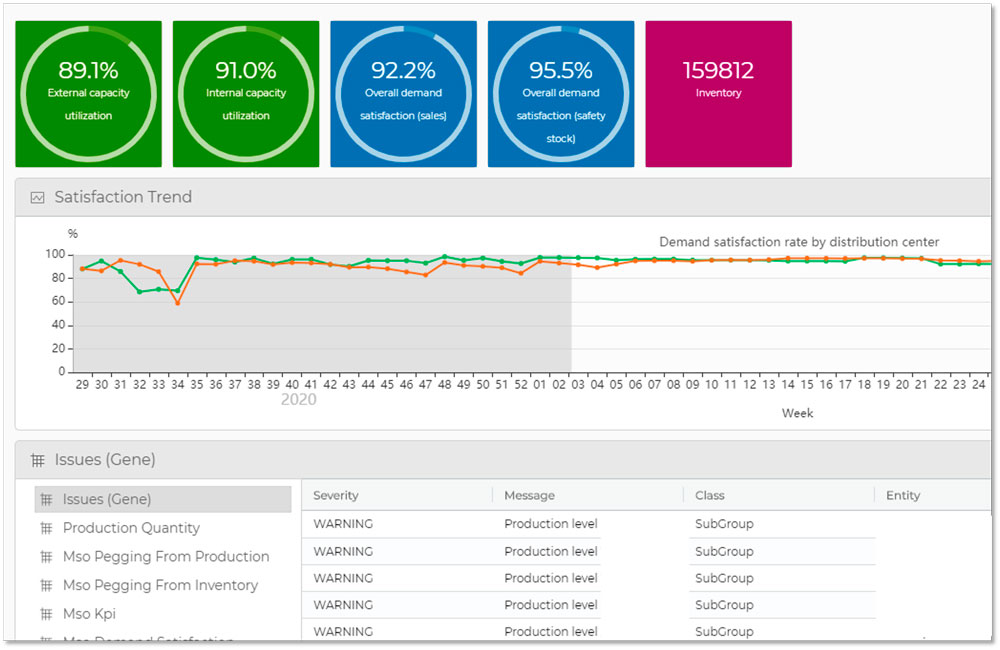

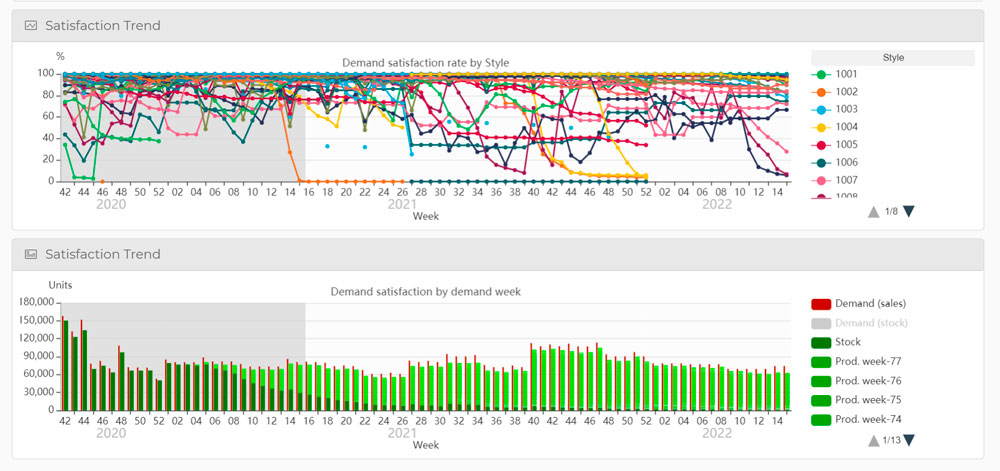

Determining where, when, and how much to produce to meet demand, inventory and efficiency targets.

Align capacity w/S&OP targets. Plan around workforce, machine, maintenance, suppliers, & subcontractor constraints

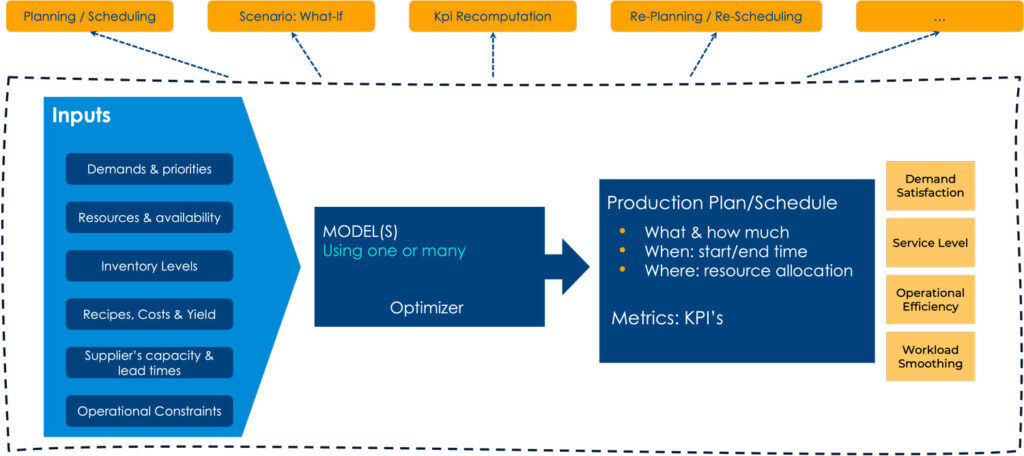

Tactical Production Planning solutions from DecisionBrain support manufacturers in producing robust and defendable production plans over multi-week or multi-month time horizons. Plans are built while factoring in constraints like:

- Production capacity

- Lot size restrictions

- Compatibility rules

- Workforce schedules

- Machine and equipment availability

- Supplier limitations

- Planned downtimes

DecisionBrain leverages powerful machine learning and mathematical optimization solvers to consider all of these constraints along with various weighted goals to produce plans that specify the quantity, timing and location of production as well as informing procurement, sourcing, and material transfers decisions. As business priorities shift or unexpected events occur, plans are quickly updated with the option to “freeze” parts of the plan if desired.

Advanced Manufacturing Planning & Detailed Scheduling Software Demo

Advanced Planning and Production Scheduling software system used by a packaging company for make-to-stock and make-to-order products. Resulted in reduced production costs, higher throughput, reduced waste and greater responsiveness to demand volatility or machine breakdowns.

Supply Chain Optimization Solutions Brochure

Download our Supply Chain Planning Solution brochure to discover 8 use cases that will make your supply chain more resilient and adaptable.