Blog

Non-Disruptive Optimized Planning Reduces Milk-Run Costs

A milk-run, in logistics, is a regular, multi-stop, round trip for either distribution or collection. Automotive manufacturers commonly use milk-runs to collect suppliers’ parts to feed their final assembly lines. Spare parts distribution to dealers and maintenance shops use milk runs, which face similar challenges. The well-known benefits of milk-runs include:

- Reduced transportation costs due to load consolidation.

- Each part’s transport costs revealed.

- Better synchronization with the assembly line’s requirements.

Reduced inventory at the plant or maintenance shop.

The transportation cost reduction is significant. Nemato and Rothengatter1 estimated Toyota Motor Thailand’s (TMT) CO2 emissions for their inbound operations with and without milk-runs. In 2010, when production was around 490,000 units, they estimated that milk-runs reduced CO2 emissions by 13.6 tons per day per factory, a 53% reduction. This CO2 reduction suggests significant savings in fuel, distances drove, driver’s time, and fleet costs.

Unfortunately, milk-runs, even involving just 25 trucks, are challenging for planners to efficiently schedule. Spreadsheets can partially do 3-D packing, but not routing. Planners need better tools to further reduce milk-run transportation costs by an additional 10%, even 15%. Moreover, with the right tools, planners will win these reductions without disrupting existing operations. Usually, these tools deliver payback within months, certainly less than a year.

Milk-Run Planning: Challenges & Constraints

To feed the assembly line with all required parts at the right time requires defining:

- Which truck collects which suppliers’ parts?

- In which sequence does each truck visit suppliers?

- At what times?

- How to efficiently pack and stack the parts in the truck.

For a typical automotive assembly plant, there can be billions of alternatives. The best alternative delivers the lowest transportation costs. To find the shortest distance traveled by the entire fleet is like a complex traveling salesman problem. It’s even more difficult because the plan must comply with the following constraints or rules:

Route Planning

The first challenge is to assign a route to each group of two to four suppliers, until all suppliers, typically a few hundred, are covered.

Not all trucks can use all roads. Low bridges, or weather conditions on bridges close routes to high-sided vehicles. Similarly, large trucks cannot use narrow, single-lane roads. Although less common, supplier’s loading bays might not accept all truck types. In addition, the driver’s hours must fit a standard shift and regulations.

Timings must be accurate. For instance, TMT requires drivers to arrive within +/- 10 minutes of their scheduled time. 15 minutes late is a compliance deviation, a KPI, which is usually under 5%.

Collection Sequence

The next step defines in which order a truck will visit suppliers in its route. Ideally, the route minimizes the distance traveled. However, the pallets are first loaded at the front. So, packing and stacking constraints influence the collection sequence.

Packing and Stacking

Inbound automotive logistics handles 10,000 different pallet types. At times, these pallets are not standard Euro or US-sized pallets. Their characteristics e.g.: footprint, volume, weight carrying capacity, and placement requirement, form a complex array. Even pallets collected from the same supplier, containing the same parts, can be different types.

Where the pallet is placed in the truck is important. Good practice places heavy pallets at the front to help stabilize the rear when cornering. Similarly, pallets containing fragile items go at the front to reduce the vibration they experience. Other pallets are “non-rotatable”, as they contain fragile items so must face a particular direction. Other pallets go near the tailgate.

Ideally, packing and stacking the pallets on the truck completely fills the space. Stacking pallets is complex, as the bottom pallets:

- Weight carrying capacity is limited.

- Have a different footprint to the upper pallets – it’s not as simple as 2 upper pallets equal a bottom pallets’ footprint.

Efficient packing often requires a planner’s experience. 3-D packing algorithms reject pallet layouts a few millimeters too wide for soft-walled trucks. In practice, such an arrangement might fit. “No Overhanging” is a common rule for upper pallets. Yet in practice, planners might allow a tiny overhang.

Disruption: Maintain Stable Routes & Collection Times

Dramatically changing milk-run plans every month is uneconomic even for plans promising significantly reduced transportation costs. The risk of assembly line disruption doesn’t justify the reward. Typically, a finished car rolls off the assembly line every minute, so stoppages cost over $1 million per hour in lost production.

Routes and collection times that remain stable from month to month reduce disruption risks. A suppliers’ workforce knows what’s to be done, by when, each day. Sending drivers out on familiar routes to familiar suppliers reduces errors and accidents.

Monthly improvements limited to the odd supplier’s collection times and a couple of experienced drivers’ routes are easily managed. Month by month these continuous improvements build to deliver significantly reduced transportation costs.

The time to find the very best plan is prior to a new model launch when all schedules are new. However, the planners must already trust their planning tools, before planning the new model’s milk-run.

The Value of Rapid Planning

Planners who create feasible plans within an hour, instead of the more usual days, can tackle value-added tasks. For instance, they can estimate the benefits of small improvements, such as:

- A different truck mix when existing trucks retire.

- The loading window at a single supplier opening perhaps an hour earlier.

If operational problems emerge, planners can replan when, e.g.

- The economy and production slow down due to Covid.

- An accident involving a truck occurs.

- A driver calls in sick.

- Bad weather/monsoon is forecast, as heavy rain reduces vehicle speeds.

- Roadworks are announced, which will cause road jams.

Why Spreadsheets Don’t Generate Good Plans

Packaged software often lacks the capability to handle special rules and constraints. So, planners use Spreadsheets. However, on an industrial scale, Spreadsheets don’t efficiently solve traveling salesmen or Sudoku-type problems.

Since there are a billion combinations of routes, collection sequences, packing and stacking arrangements, planning takes days. Spreadsheets can apply rules but not automatically search for a better plan. To simplify the problem, planners plan sequentially:

- First plan the routes.

- Then the collection sequence.

- Finally, pack & stack the pallets.

Then problems emerge as e.g., there isn’t sufficient space to pack and stack the pallets. So, planners start again with a different route or collection sequence. If they are highly experienced, they’ll find a feasible solution. However, they don’t know if an even better solution is possible, there are too many alternatives.

Finding a better, non-disruptive, lower-cost transportation plan requires solving all three problems together, not sequentially. This requires more sophisticated tools.

How Constraint Programming Finds Better Plans

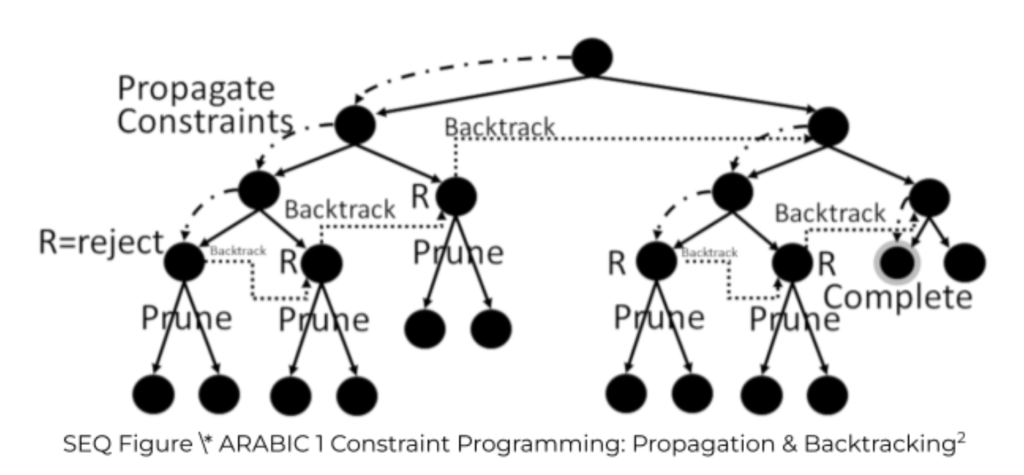

Constraint programming is a well-proven branch of Artificial Intelligence (AI). First, it creates a tree of all solutions. Then it rejects the infeasible plans that break a rule or constraint. Then it identifies the best plan out of the remaining feasible plans. The technique is a bit like a scaled-up version of how people solve Sudoku puzzles.

Constraint programming requires programmers to code the criteria to measure what the best solution looks like, e.g., minimum total distance traveled. Then, programmers code the constraints, e.g., the truck loading constraints.

Like Sudoku, finding a feasible solution involves repeatedly applying constraints to eliminate unfeasible options. A tree of potential solutions is one way to picture how constraint programming works, as in Figure 1. First, propagate a constraint. The solver rejects or prunes potential plans if they break this constraint. In this process, something is learned about the feasible solution. Backtracking applies this new knowledge to eliminate other infeasible solutions. Step and repeat, until feasible solutions remain. In practice, the algorithms are more sophisticated.

Finally, the solver tests every feasible solution against the objectives to identify the very best solution. Planners using spreadsheets or packaged solutions are usually happy when they find one feasible solution.

Non-Disruptive, Optimized Milk-Run Planning at TMT

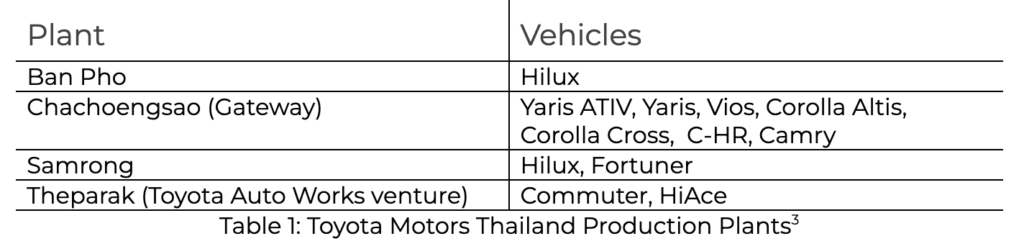

Toyota Motors Thailand (TMT) has four assembly plants at Samrong, Chachoengsao (Gateway), Ban Pho, and Theparak (Toyota Auto Works venture), assembling the vehicles in Table 1.

Before Covid, total 2019 production was 570,850 units, of which 264,775 units were exported. Currently, TMT has around 270 suppliers and locally procures around 80% of the total parts’ value.

Toyota HQ in Japan defines each plant’s production for the coming month. The TMT planning team plans assembly, parts orders and milk runs. Using spreadsheets, 5 planners took 2.5 days to develop the milk-run plan.

Complicated rules determined the number of parts deliveries per supplier per day. The number depends on the supplier and order volume and is an even number between 2 and 12, as each plant runs 2 shifts.

The planners handled many of the aforementioned constraints. However, access to the supplier’s plants was easy as they’re located on industrial estates accessible by good roads. Each plants’ milk-run network comprises about:

- 100 routes,

- 200 to 300 trips,

- 70-90 trucks.

The truck fleet mainly comprises 4.3 ton, six-wheel trucks due to traffic congestion. Where possible, TMT uses some 12-ton, 10-wheel trucks. A particular route uses a particular truck type.

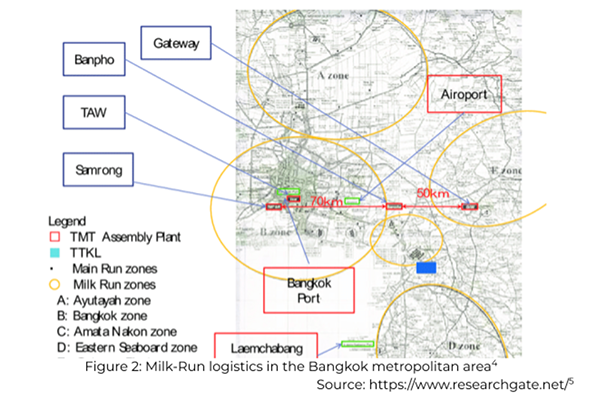

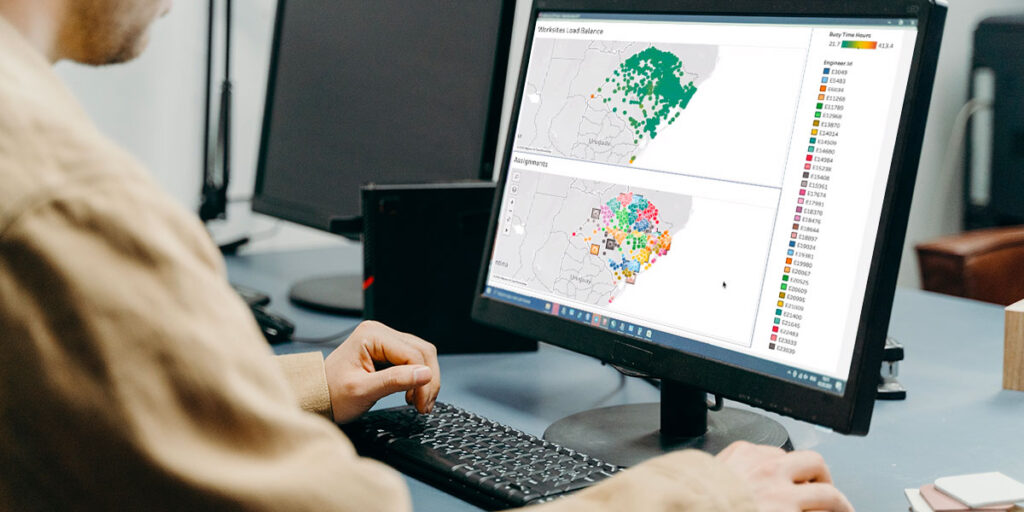

The planners divided the suppliers into five zones, shown in figure 2. This means trucks collecting parts in Zone A don’t collect parts in Zone B, around Bangkok.

The planners divide each zone into sub-zones, and further divide each sub-zone into sub-sub-zones. They then specify the order for drivers to visit suppliers in each sub-sub-zone.

TMT’s key requirement was to minimize driver and supplier disruption, i.e., next months’ plan should be like this months’ plan. To cost-justify DecisionBrain’s project, TMT expected a 2% transportation cost reduction plus a faster planning process.

How DecisionBrain’s Planning Tool Minimized Disruption

DecisionBrain’s first step was to recreate the planners’ spreadsheet plans, which built the planners’ trust in the new system. The planners’ spreadsheet data was good. Nevertheless, complex differences emerged, which together DecisionBrain and TMT resolved. The root cause could lie in either TMT’s spreadsheets, the routing/packing algorithms, or DecisionBrain’s code.

DecisionBrain configured their Constraint Programming tool to search for better plans. DecisionBrain minimized disruption/change using local search, not global search.

A global search means starting at the top of the tree in figure 1. In practice, this means searching through about a billion possibilities. The result is a great plan, that’s so different it disrupts operations.

Local search involves starting lower down the tree, which reduces the billion total possibilities/alternatives to perhaps a hundred, sometimes tens of thousands. Easily managed, non-disruptive improvements emerge by applying rules such as:

- Maintain separate routings for each of the five zones.

- Don’t “improve” routes with over, say, 80% truck utilization.

- Distribute the load from a partially loaded truck onto other trucks, which involves searching about ten thousand alternatives.

- Swap a partially loaded truck for a smaller truck, which involves searching about a hundred alternatives.

- If two trucks visit a common supplier, swap some of their other visits, and see if the plan improves.

- Since the Samrong and TAW plants are geographically close, allow partial unloading at one plant, then drive to the second plant to complete unloading.

The tool also enabled planners to limit changes. For instance, planners can specify routes & drivers that mustn’t change, as may be the drivers are learning routes.

To further reduce disruption, planners approve every suggestion. For instance, the planners might know a route is heavily congested. Hence the timings require greater slack. The only time the planners optimize routes using global search is when planning a new model’s milk-runs.

The Results

Using DecisionBrain’s tool, during the first few months after go-live, the planners achieved a 2% to 10% transportation cost reduction, compared to previous months, typically 8%. Occasionally, the reduction was 15%. The tool enables continuous improvement, so by now, transportation costs are significantly lower.

DecisionBrain estimates the project payback period to be 8 months. Overall, the project took 2½ DecisionBrain consultants about 10 months. Given the data in this paper, we estimate planning optimization saves over 1000 metric tons of CO2/year. European carbon futures are currently around €80/tonne6 .

Instead of requiring 2.5 days, planners now generate monthly milk-run plans within an hour. This new flexibility allowed Toyota to plan new non-disruptive milk runs every 2 weeks when the economy and car production slowed during Covid.

References

1. Toshinori Nemoto, Hitotsubashi University, Tokyo, Japan, [email protected]. Werner Rothengatter, Karlsruhe Institute of Technology, Karlsruhe, Germany

2. Inspired by https://www.researchgate.net/figure/Backtracking-algorithm-taken-from-1_fig2_316610194, uploaded by Illya Vernich

3. Wikipedia Toyota Motor Thailand

4. Toyota Thailand

5. https://www.researchgate.net/figure/Milk-Run-logistics-in-the-Bangkok-metropolitan-area_fig1_238384844 From Milk-Run Logistics by Japanese automobile manufacturers in Thailand, Nemoto, Hayashi & Hashimoto.

6. Europe’s Carbon Price Has Almost Tripled in 2021

About the Author

Filippo Focacci, PhD is Co-founder and CEO at DecisionBrain. Before founding DecisionBrain, Filippo worked for ILOG and IBM for over 15 years where he held several leadership positions in consulting, R&D, product management and product marketing in the area of supply chain and optimization. He received a Ph.D. in operations research from the University of Ferrara (Italy) and has over 15 years of experience applying O.R. techniques in industrial applications in several optimization domains.

About the Author

Guillaume Vantroeyen is the Head of Solution Delivery at DecisionBrain, he is in charge of the entire project life cycle of client-related projects. Guillaume received an Engineering Degree in Mathematics and a Master’s degree in Operations Research at the University of Dauphine in Paris in 2013. Since then, he has been refining his knowledge of optimization models for supply chain network planning, logistics, and workforce planning through his experiences in consulting and software development.