Blog

Lot Sizing: Real-World Challenges and Expert Insights

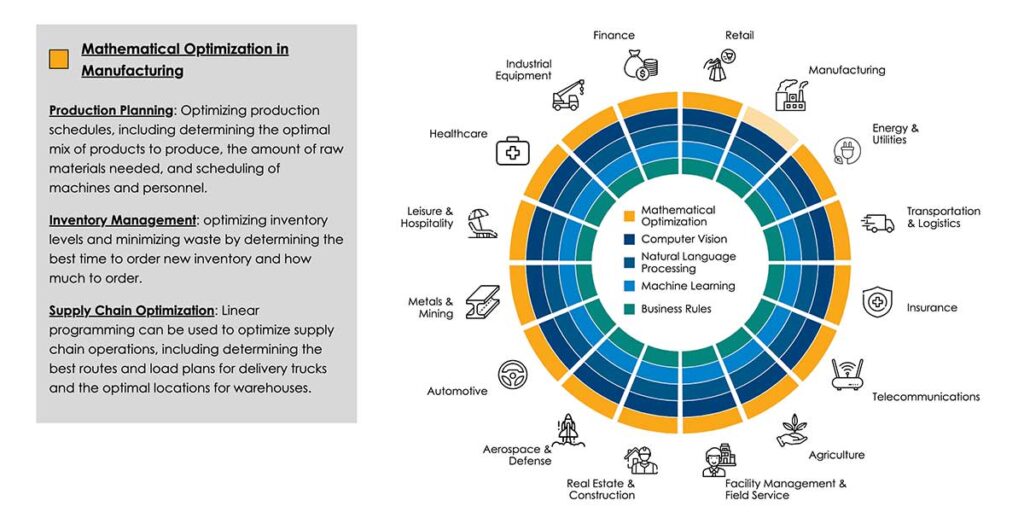

Lot sizing, sometimes referred to as batching, is most associated with manufacturing and supply chain planning use cases, such as material resource planning (MRP) and production scheduling. However, to researchers and practitioners of mathematical optimization, lot sizing problems are everywhere, including:

- Manufacturing Planning & Scheduling: Determining production batch sizes

- Inventory & Supply Chain Planning: How to group and position inventory across stores and warehouses

- Tactical Logistics Planning: When (eg by week) to move what sized batches of product from factory to warehouse

- Maintenance Planning: Creating smart maintenance activity bundles

- Marketing Campaigns: Deciding how much of your marketing budget to allocate to different channels (tradeshows, advertising, social media, etc.)

- Finance/Forex Trading: Determining the right quantities (lots) of different currencies to trade based on risk/return requirements

In this post, we’ll explore this topic through the lens of real-world examples and insights from Sébastien Beraudy, a PhD in Operations Research and a member of the DecisionBrain team.

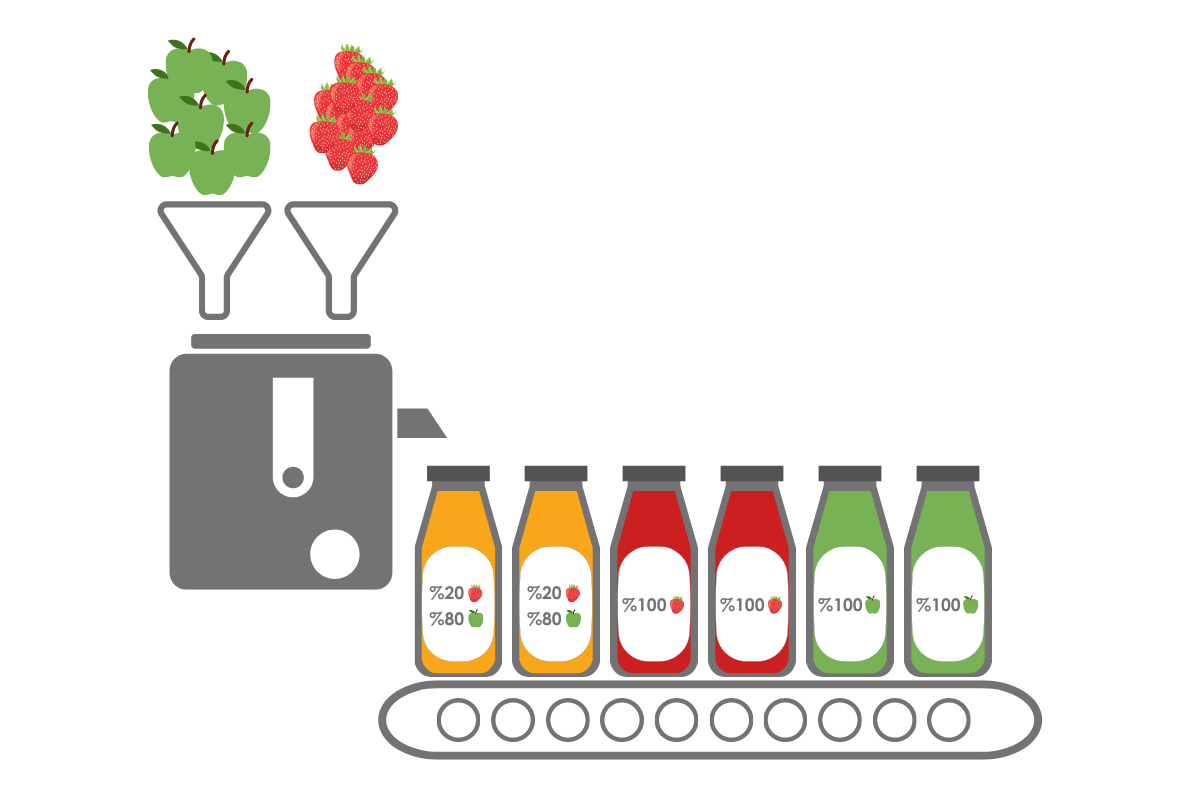

The Juice Factory: Balancing Perishability and Costs

Imagine you run a factory that produces mixed fruit juices. You have a variety of fruits like apples and strawberries, each with different costs and demand profiles. Strawberries are more expensive but highly popular, while apples are cheaper but less in demand. Your goal is to produce the right mix of juices to meet customer demand without wasting any fruit or incurring unnecessary costs.

In this scenario, you might produce four types of juices: pure apple, pure strawberry, a 5% strawberry 95% apple blend, and a premium 20% strawberry blend. Lot sizing involves determining the optimal quantity of each type of juice to produce in each time period. You need to balance the costs, meet demand, and minimize waste. If you produce too much of the premium blend, it might spoil before it’s sold. If you produce too little, you might miss out on sales and disappoint customers.

Sébastien explains, “Lot sizing is like solving a complex puzzle where all the pieces must fit together perfectly. You need to consider a lot of elements like production costs, storage limitations, the perishability of different ingredients, etc. It’s a challenging problem, but getting it right can lead to significant cost savings and efficiency gains.”

The Freeway Scenario: Prioritizing High-Importance Orders

Now, let’s look at another type of lot sizing problem. Picture a busy freeway with cars traveling at a constant speed. Unexpectedly, an ambulance needs to get through, so all of the cars must adjust their speed to let it pass. This is similar to a manufacturing line that needs to prioritize a high-importance order.

In manufacturing, you might have a standard production schedule, but occasionally a high-priority order comes in that needs to be expedited. This means rearranging your production schedule to accommodate the urgent order without causing too much disruption to the regular flow. If you can’t adequately model different lead times, it can result in a totally infeasible schedule. Like cars on the freeway not seeing the accident alert on their phone right away – they might miss to exit when they could have, or might miss to re-enter when the accident has been cleared, ultimately arriving at their destination too late.

Sébastien likens this to managing lead times in lot sizing. “Lead times can be unpredictable and variable, much like traffic on a freeway. Averaging lead times might seem like a simple solution, but it doesn’t account for variability and unexpected delays – such as when road construction is happening, similar to a manufacturing station being down or a raw material not arriving on time. If you can’t model these variations accurately, you might end up with a schedule that simply doesn’t work in practice, which could mean chaos on the production floor!”

Why Lot Sizing Problems are Hard – The Lead Times Example

The lead time example is an interesting case for both academics and industry professionals because it illustrates how the addition of a single constraint can drastically affect the solvability of lot sizing problems. This, in turn, impacts the ability of software systems to generate effective production schedules.

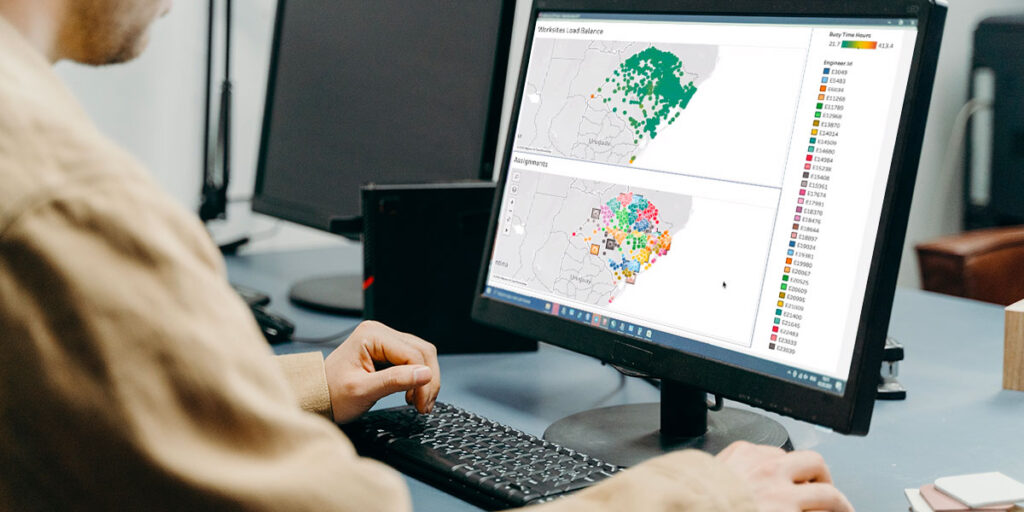

First, let’s review how lot sizing applies in manufacturing. Changing over from producing one product to another (e.g., the cleaning required to switch from red paint to white paint) reduces efficiency, creating a temptation to run large production batches, meaning large lot sizes. However, this results in high inventory levels (leading to the issues discussed in our blog post on inventory optimization) and potential service issues when demand varies. So obviously we have to find balance by optimizing the lot sizes so that we can provide great service but with minimal inventory carrying costs.

However, when creating an effective schedule, the changeover time—which includes everything from the time it takes to receive white paint from the supplier to the cleaning and preparation time for applying the white paint, and even the drying time—needs to be accurately specified and considered by the scheduling (optimization) system. This is easier said than done. Here’s why:

- Variability: Lead times can be highly variable and unpredictable due to factors like supplier reliability, transportation delays, and production issues. Averaging lead times oversimplifies this variability, leading to inaccuracies in planning.

- Complex Interactions: Lead times interact with other constraints (e.g., production capacity, storage limitations) in complex ways. A delay in one part of the supply chain can have cascading effects, complicating the optimization process.

- Dynamic Nature: Lead times can change over time due to market conditions, changes in suppliers, or internal process improvements (eg switching to more environmentally friendly paint increases the curing time). Static models that use averaged lead times fail to adapt to these changes.

- Non-Linearity: Lead times don’t always increase in a straight line with the load. For instance, the more you produce, the longer each unit might take, but not in a simple, predictable way. To handle this, one approach is to look at past data to see how lead times changed and then break this into smaller, more manageable pieces that can be used in planning. Another approach is to use simulations to see how different production plans affect lead times and then adjust the plan accordingly. This complexity makes the problem harder to solve with straightforward methods.

Many other constraints, such as production capacities, shelf-life limitations, or resource availability, can similarly complicate the problem and require sophisticated approaches to address effectively.

Procurement Lot Sizing: Balancing Cost and Inventory Management

Procurement lot sizing is yet another common application. This is about optimizing purchase quantities to balance cost savings and inventory management. Bulk purchases offer lower unit costs but that also means increased carrying costs, so it may not make sense for items with uncertain demand or short life cycles. Factors like packaging and transportation costs may also need to be considered. Effective planning tools should integrate these costs along with the various business objectives to achieve optimal procurement lot sizes. Just as important is to keep the lot sizes dynamic so they stay in sync with demand and supply conditions.

Conclusion & Resource for Deeper Understanding

Lot sizing is a critical aspect of many supply chain planning and scheduling problems. Whether you’re managing inventory, optimizing manufacturing processes, or streamlining procurement strategies, getting lot sizing right is incredibly important.

While many software applications handle lot sizing to some degree, adding a new constraint can drastically complicate the problem. This is why it’s worth consulting experts in both supply chain management and operations research to assess the feasibility of your specific application.

Addressing these challenges requires expertise and innovative solutions. At DecisionBrain, our team, including experts like Sébastien, is dedicated to developing efficient and effective strategies to help businesses thrive in today’s competitive environment. Understanding and tackling the complexities of lot sizing can lead to substantial benefits, making the effort well worth it.

For a deeper dive into the technical aspects of lot sizing and lead time variability, you can read Sébastien’s PhD dissertation here.

Facing lot sizing challenges in your operations?

Our team of experts at DecisionBrain is here to help.

DecisionBrain is a leading provider of advanced decision support software that is used to solve the world’s hardest supply chain, workforce and maintenance planning, scheduling & logistics optimization problems. With over 400 person-years of experience in machine learning, operations research and mathematical optimization, DecisionBrain delivers custom-fit decision support systems where packaged applications fall short. Read more about us or contact us to talk about our solutions!