Blog

What is APS Software?

Of course you didn’t. Because no matter how well you plan, surprises will happen – even those you just can’t predict. Which is why you need intelligent and dynamic planning – or in industry lingo: Advanced Planning & Scheduling (APS) capabilities.

But this can be really hard to implement, especially in complex and fast-moving environments.

That’s where APS systems come in.

What is an Advanced Planning and Scheduling (APS) System?

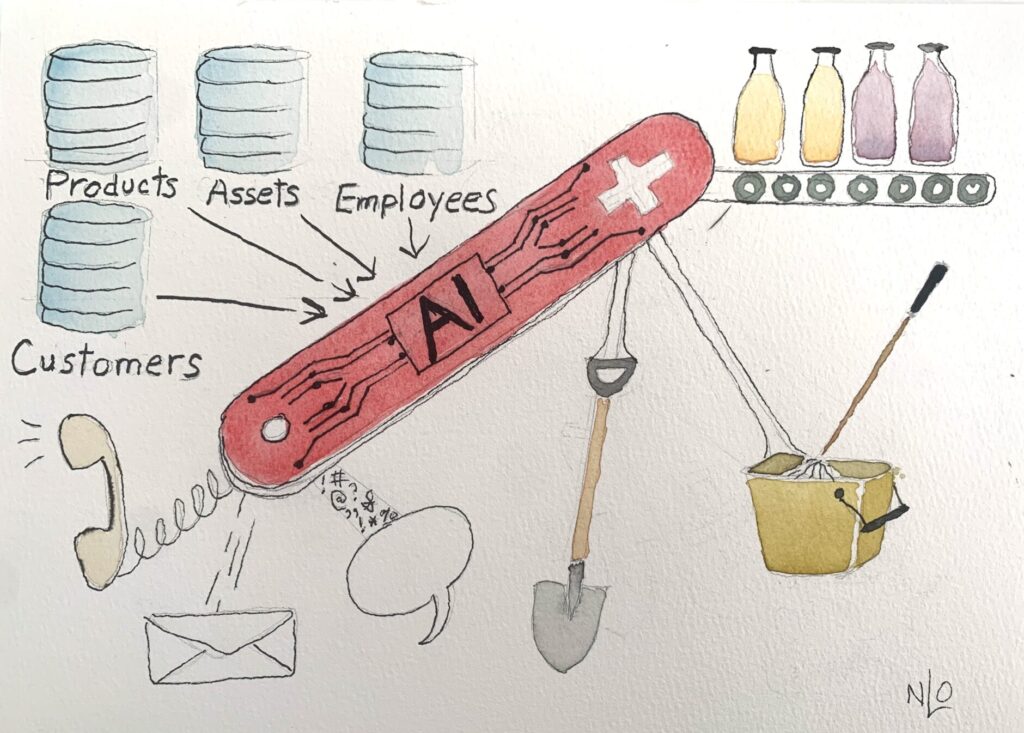

An APS system is a software application that supports you in building and adjusting plans and schedules that actually work for you. It’s different from calendaring apps, Microsoft Project or even Excel. An APS system has a lot of intelligence built in and the capability to handle the kinds of problems that would break Excel.

Generally speaking, most APS systems offer the following capabilities:

- Integration with the systems that hold your data – HR, Time & Attendance, ERP, MRP, TMS

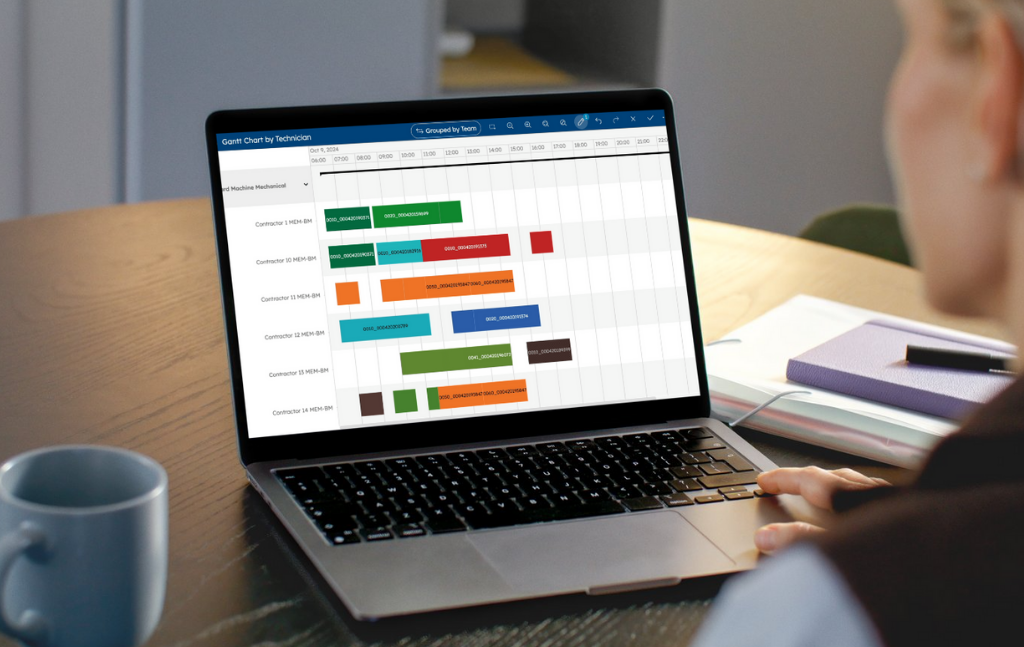

- Planning/Scheduling Visualizations – Interactive Gantt charts, Maps, Tables, Filters

- Plan/Schedule Generation – triggered by a button or run automatically at predefined times

- Plan/Schedule Adjustment with feedback – for example, if you change the plan by clicking on a scheduled activity in a Gantt chart and dragging it to another location, which breaks a constraint, the system lets you know

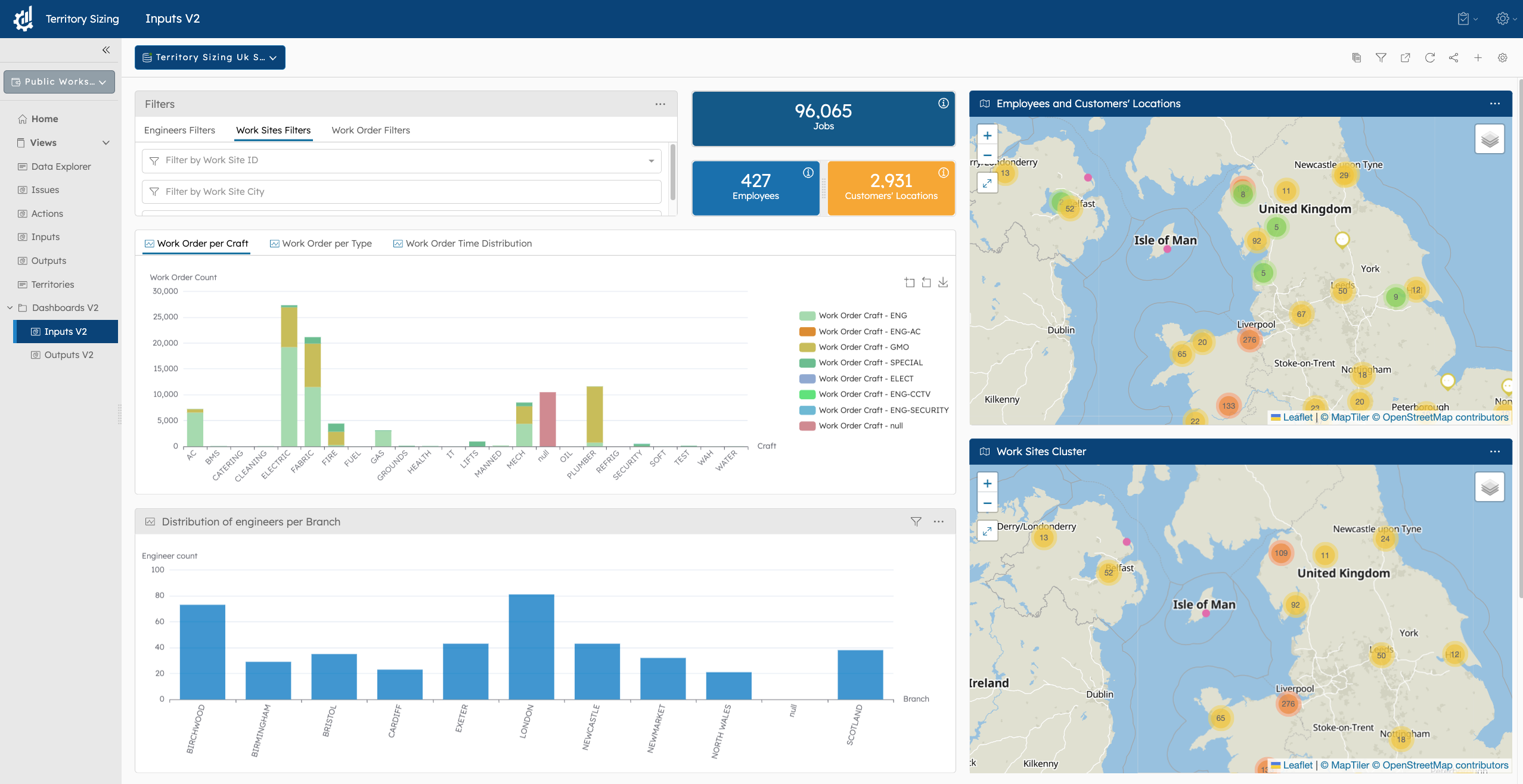

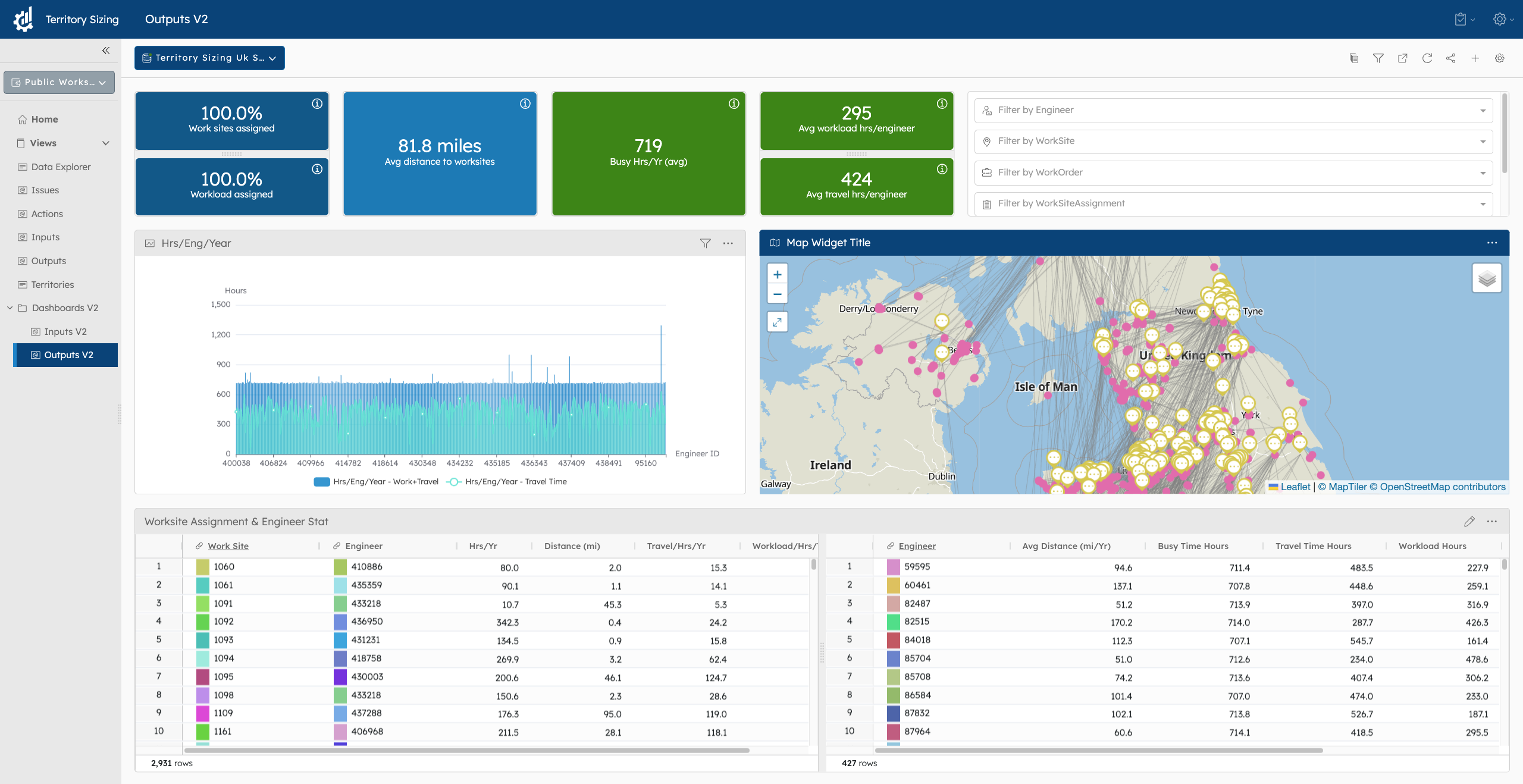

- Analytics Dashboards and KPIs – so you can evaluate the goodness of your plans and schedules

- Simulation, Scenario Testing and Comparison – so you can evaluate the tradeoffs between different plans or schedules in terms of your specific business KPIs

- Forecasting and Demand Planning – not all APS systems offer this and those that do have different levels of sophistication – but one way or another, the APS systems needs to have input on what to plan for.

Who Needs Advanced Planning and Scheduling?

If you face three or more of the following challenges, you probably need an APS system:

- You’re trying to plan or schedule your supply chain, logistics, manufacturing, maintenance, or workforce resources or activities.

- Your plan is big – hundreds or more SKUs, vehicles, workers, machines, locations, work orders, etc.

- Planning takes a lot of time and relies heavily on manual intervention.

- Your environment is dynamic, necessitating frequent replanning.

- A lot of rules and constraints that bring planning complexity.

- You’re having trouble balancing across competing objectives, like efficiency, service level and/or workload balance or smoothness.

- Suboptimal plans are costing the business $100,000 or more per year.

Common Use Cases for APS Systems

Manufacturing and Supply Chain

- Manufacturing Capacity Planning

- Production Planning

- Factory Detailed Scheduling

- Inventory Planning

- Strategic Network Design

- Network Flow Optimization

- Route Planning

- Load Building

- Operational Scheduling

- Spare Parts Planning

Discover Our APS solutions

DecisionBrain offers APS solutions in Manufacturing, Supply Chain, Logistics, Workforce and Maintenance.

DecisionBrain is a leading provider of advanced decision support software that is used to solve the world’s hardest supply chain, workforce and maintenance planning, scheduling & logistics optimization problems. With over 400 person-years of experience in machine learning, operations research and mathematical optimization, DecisionBrain delivers custom-fit decision support systems where packaged applications fall short. Read more about us or contact us to talk about our solutions!