Cas d'utilisation de l'IA dans 16 secteurs d'activité : Visionnez notre infographie interactive !

Business Rules

Pricing and promotions: setting prices and applying promotions using rules based on sales data and customer behavior.

Inventory management: managing inventory levels by applying rules to determine when to order new stock and how much to order.

Customer service: improving customer service by applying rules to determine the best course of action for customer inquiries and complaints.

Machine Learning

Product recommendations: signaling to retailers which products to recommend based on purchase history and other data that correlates with purchase or uplift likelihood.

Inventory management: ML-based systems can be used to predict demand. These predictions can then be used to optimize stocking levels.

Price optimization: Machine learning can help retailers optimize prices for different products, customers or market segments based on market trends, demand, customer attributes and other factors.

Natural Language Processing

Chatbots and voice assistants: for customer service and support

Sentiment analysis of customer reviews: and feedback to improve product development and marketing strategies

Automated product descriptions: and categorization for e-commerce sites

Natural language search engines for online shopping

Computer Vision

Object Detection: identify products on store shelves, helping retailers manage inventory and prevent theft.

Customer Analytics: analyze customer behavior in-store, providing insights into shopping patterns and improving store layout.

Mathematical Optimization

Product Assortment Planning: Deciding the best mix of products to stock in a given store based on forecast, margin, competition, bundling and other factors.

Layout Optimization: How to lay out product categories or individual products on floors, shelves, pegboards or other displays based on adjacency, profitability, compatibility and various other goals and constraints.

Store Stock Replenishment: Planning and scheduling of the replenishers who restock store shelves for vendor-managed inventory (VMI).

Strategic Network Design: Identifying the optimal location for stores, warehouses and fulfillment centers. These models can take into account factors such as land cost, proximity to transportation, and availability of utilities.

Business Rules

Quality control: improving quality control by applying rules to analyze production data and identify potential issues.

Supply chain management: determining the best suppliers and shipping methods for different products based on business rules.

Production planning: rule-based production planning to determine the best sequence of operations and resources needed for each product (note that optimization-based approaches which incorporate business rules as « constraints » may be superior in complex manufacturing environments.

Machine Learning

Quality control: ML models are used by manufacturers to monitor production processes and detect defects in products.

Predictive maintenance: Machine learning can help manufacturers predict when machines and equipment are likely to fail, allowing for preventative maintenance to be scheduled. The scheduling part is often solved using optimization-based planning and scheduling systems.

Supply chain optimization: ML-based forecasting models are often used as an input into systems that make a variety of supply chain optimization decisions, such as procurement, inventory management to transportationa and logistics planing.

Natural Language Processing

Quality control and defect analysis: using NLP to analyze text and image data

Automated report generation: and analysis for predictive maintenance and downtime reduction

Chatbots and voice assistants: for customer service and support

Natural language search engines: for manufacturing data analysis

Computer Vision

Quality Control: identify defects in products, reducing waste and improving quality control.

Process Automation: automate manufacturing processes, improving efficiency and reducing labor costs.

Mathematical Optimization

Production Planning: Optimizing production schedules, determining the optimal mix of products to produce, the amount of raw materials needed, and scheduling of machines and personnel.

Inventory Management: Set safety stock levels, reorder points, and inventory replenishment strategies balancing cost and service level.

Capacity Planning: Assess, model and optimize production capacity to align with long-term demand and goals.

Sales & Operations Planning: Align demand, sales capabilities and inventory strategies to balance service level, efficiency.

Business Rules

Resource optimization: applying rules to determine the best allocation of energy and utility resources to meet demand – depending on complexity, optimization-based approaches which incorporate business rules as « constraints » may be superior.

Asset management: applying rules to determine when to repair or replace equipment and manage preventative maintenance – but for complex asset maintenance planning problems, optimization-based approaches are superior.

Compliance: BRMS can help energy and utility companies comply with regulations by applying rules to ensure that all processes and procedures are followed correctly.

Machine Learning

Predictive maintenance: Machine learning can help energy and utilities companies predict when equipment is likely to fail, allowing for preventative maintenance to be scheduled.The scheduling piece if often solved using optimization-based systems.

Demand forecasting: Machine learning can help predict demand for energy and optimize supply accordingly, reducing waste and improving efficiency.

Natural Language Processing

Automated report generation and analysis: for predictive maintenance and downtime reduction

Chatbots and voice assistants: for customer service and support

Sentiment analysis: of customer feedback to improve product development and marketing strategies

Natural language search engines: for energy and utilities data analysis

Computer Vision

Asset Monitoring: monitoring energy infrastructure, detecting potential issues and improving maintenance.

Safety Monitoring: monitoring safety in hazardous environments, improving worker safety and reducing accidents.

Mathematical Optimization

Network Optimization: Planning the design and operation of power distribution networks by taking into account factors such as load balance, voltage regulation, and equipment capacity to develop optimal network configurations.

Asset Optimization: Optimizing the use of assets such as power plants and transmission lines, taking into account factors such as capacity, efficiency, and maintenance costs. This can help utilities to maximize the value of their assets while minimizing costs.

Demand Response Management: Managing demand response programs that incentivize customers to reduce energy consumption during peak periods. These models can determine the optimal allocation of resources to meet demand while minimizing costs.

Resource Planning and Scheduling: Planning & scheduling the use of resources such as power plants, renewable energy sources, and storage facilities considering factors such as demand, weather conditions, and equipment availability to develop optimal schedules.

Business Rules

Routing and scheduling: rules can be used to make routing and scheduling decisions for deliveries and pickups, but for complex logistics decisions, optimization-based approaches are superior.

Asset management: applying rules to determine when to repair or replace vehicles and equipment – but for complex asset maintenance planning problems, optimization-based approaches which incorporate business rules as « constraints » may be superior.

Compliance: applying rules to ensure that certain processes and procedures are followed correctly.

Machine Learning

Predictive maintenance: predicting when vehicles and equipment are likely to fail, allowing for preventative maintenance to be scheduled. Note that the planning and scheduling of the maintenance activities is often handled using optimization technology.

Real-time tracking: ML can be used to track the location of vehicles and shipments in real-time, improving visibility and reducing the risk of lost or stolen goods.

Natural Language Processing

Automated shipment tracking: and status updates using NLP to analyze text and location data

Chatbots and voice assistants: for customer service and support

Automated report generation and analysis: for predictive maintenance and downtime reduction

Computer Vision

Autonomous Vehicles: guiding autonomous vehicles, detecting obstacles and improving safety.

Inventory Management: monitoring inventory levels in warehouses, improving logistics and reducing costs.

Mathematical Optimization

Route Optimization: Territory sizing, route planning, load balancing, scheduling and dispatch.

Load Optimization: Determining the best way to fill trailers or containers considering stacking, LIFO, volume and weight constraints.

Supply Chain Optimization: Optimizing supply & distribution network sructure, optimizing allocation of inventory, and the most efficient transportation routes.

Port/Terminal Logistics: Container load sequencing, tugboat scheduling, berth allocation.

Business Rules

Underwriting, quoting & risk assessment: assessment of risk and underwriting of policies using rules applied to customer and vehicle/property data – also supports quote generation.

Claims management: managing of claims by applying rules to determine if a claim is valid or not and automate the claims processing.

Fraud detection: detecting fraudulent activities by applying rules to identify suspicious claims and flag them for investigation.

Machine Learning

Risk assessment: helping insurance companies assess the risk of insuring a particular person or property based on historical data and other relevant factors.

Claims fraud detection: helping insurance companies process claims more efficiently by automatically identifying those claims that are potentially fraudulent.

Personalized policies: Companies can create personalized policies with custom-fit pricing based on customers’ individual risk factors and by taking in wearable device or automotive sensor data or other relevant data.

Natural Language Processing

Fraud prevention: using NLP to analyze text data

Chatbots and voice assistants: for customer service and support

Sentiment analysis: of customer feedback to improve product development and marketing strategies

Insurance Data Analysis: Using natural language search engines

Computer Vision

Claims Processing: assessing damage and processing insurance claims, improving accuracy and efficiency.

Risk Assessment: analyzing images and videos, identifying potential risks and reducing insurance fraud.

Mathematical Optimization

Portfolio Optimization: Optimizing investment portfolios in order to determine the optimal allocation of assets while minimizing risk.

Claims Handling: Assigns adjusters based on proximity, expertise, workload, and claim urgency for faster settlements.

Business Rules

Billing and pricing:automatic billing and pricing for telco services by applying rules to analyze customer usage and apply appropriate charges.

Network management: improving network reliability using rules to monitor and alert on network performance or other early indicators of potential issues.

Service level agreements: using rules to ensure that service level agreements are met and penalties are applied when necessary.

Machine Learning

Network optimization: optimization of network performance by predicting traffic patterns and identifying bottlenecks.

Customer churn prediction: Predicting which customers are likely to churn so that telcos can take steps to prevent them from leaving.

Network security: ML models can help telcos detect and prevent cyber threats by analyzing network traffic and identifying suspicious patterns.

Natural Language Processing

Chatbots and voice assistants: for customer service and support

Sentiment analysis: of customer feedback to improve product development and marketing strategies

Natural language search engines: for network and data analysis

Automated call center routing and ticket classification: using NLP

Computer Vision

Network Monitoring: monitor network infrastructure, detecting potential issues and improving reliability.

Video Analytics: analyze video content, providing insights into customer behavior and improving advertising targeting.

Mathematical Optimization

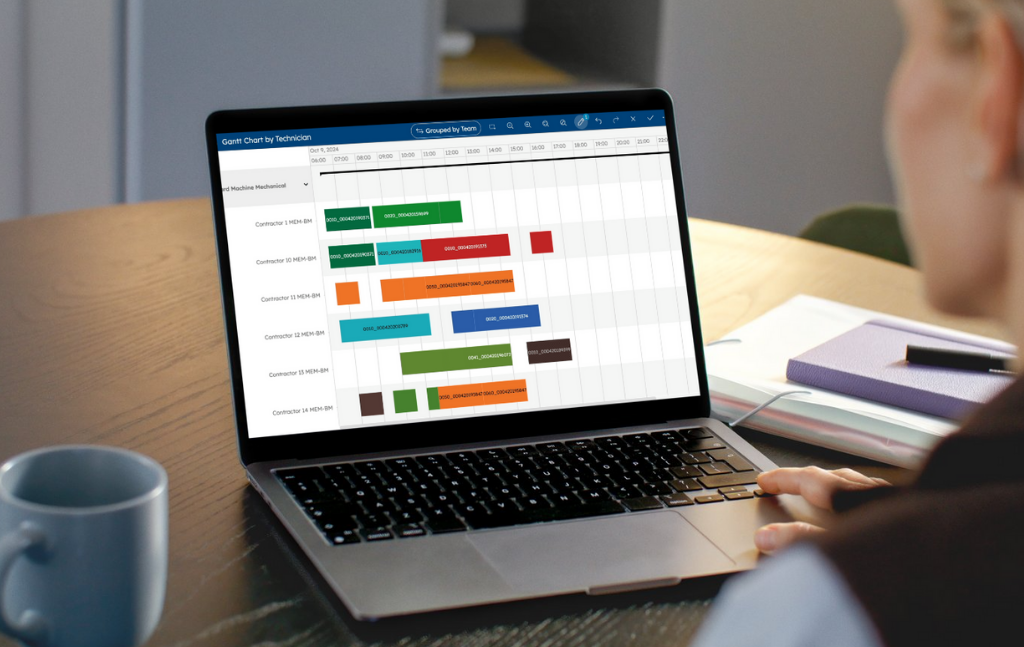

Field Operations Planning & Scheduling: Dynamic job/task assignment, scheduling & routing of workers based on location, skills, job priority, service level.

Strategic Network Planning: Expansion planning by determing tower and equipment placements in order to maximize coverage while managing costs.

Project Planning: Optimizing the planning and allocation of resources to construction and upgrade projects while better forecasting and controlling schedules and costs.

Maintenance Planning: Determining the optimal maintenance policy of network components, forecasting the maintenance period, creating maint. packages & optimal bundling into monthly/weekly plans.

Business Rules

Crop management: management of crops by applying rules to determine when to plant, water, and fertilize crops based on soil moisture, weather patterns, and other factors.

Resource optimization:resource usage decisions can be made based on rules to determine the best allocation of water, fertilizer, and other resources to maximize crop yield. Depending on complexity, optimization technologies may be a better fit.

Pest management: pest management decisions can be improved by applying rules to determine the best pest control methods based on crop type, location, and other factors. Depending on the complexity, optimization technologies which incorporate business rules as « constraints » may be superior.

Machine Learning

Crop monitoring: hleping farmers monitor crop health and more quickly detect potential issues such as pests or disease.

Yield prediction:predicting crop yield based on weather patterns, soil quality, and other relevant factors.

Soil analysis: analysis of soil data can give insights that are help improve decisions about fertilizer and other inputs so that crop quality and yield are improved.

Natural Language Processing

Crop monitoring: and management using NLP to analyze text and image data

Chatbots and voice assistants: for customer service and support

Natural language search engines: for agriculture data analysis

Automated report generation and analysis: for predictive maintenance and downtime reduction

Computer Vision

Crop Monitoring: Computer vision can be used to monitor crop health and growth, improving yield and reducing waste.

Livestock Monitoring: Computer vision can be used to monitor livestock, improving animal welfare and reducing losses.

Crop monitoring: soil analysis, and disease detection

Mathematical Optimization

Resource Allocation: Determining the optimal allocation of resources such as water, fertilizer, and pesticides, to improve crop yields while minimizing waste.

Grain Storage and Logistics: Planning and scheduling workforce to pickup, distribution, cleaning or other activities based on location, skills, certifications, and harvest, demand and capacity data.

Inspection Planning & Scheduling: Dynamically allocating inspectors to sites and creating weekly plans/schedules based on inspection type, location, skills, site requirements & service levels to fulfill both regular/planned inspections and reactive jobs.

Business Rules

Workforce management: In some cases, facility management and field service companies can improve the management of their workforce by applying job assignment and scheduling rules, however, optimization-based approaches are often superior.

Maintenance management: applying rules to determine when to repair or replace equipment and manage preventative maintenance – but for complex asset maintenance planning problems, optimization-based approaches which incorporate business rules as « constraints » may be superior..

Machine Learning

Predictive maintenance: ML models can predict when equipment is likely to fail, allowing for preventative maintenance to be scheduled. The scheduling is often solved through optimization-based system.

Asset tracking: ML models can track the location and condition of equipment and assets, improving visibility and reducing the risk of loss or theft.

Service scheduling: Service scheduling can be optimized by first using ML models to predict which assets are likely to require maintenance or repair in the near future and then feeding those predictions into optimization-powered planning and scheduling systems.

Natural Language Processing

Service Request Processing: Automatic categorization of service requests.

Chatbots and voice assistants: for customer services and support.

Report Generation: NLP can be used to generate reports automatically based on data collected from various sources.

Computer Vision

Predictive Maintenance: monitoring equipment, detecting potential issues and improving maintenance.

Asset Tracking: tracking equipment or vehicles to to ensure they are being used correctly or in compliance with rules and regulations.

Security Monitoring: to detect unusual activity or intrusions.

Mathematical Optimization

Field Service Dispatching, Routing and Scheduling: Dynamic job/task assignment, scheduling & routing of technicians, cleaning crews & other employees based on location, skills, job priority, service level, parts availability, etc in a way that balances across cost, service level and employee satisfaction KPIs.

Dynamic Maintenance Planning: Determining the optimal maintenance policy of each asset/facility, forecasting the maintenance period, creating maint. packages & optimally bundling them into monthly/weekly/daily plans.

Strategic Workforce Planning: Sizing of service teams, definition of optimal skillstes and working shifts, ideal usage of 3rd party contractors and temporary workers.

Territory Sizing: Definiting the optimal territory size for each mobile worker to ensure balanced workload and minimize travel time.

Business Rules

Project management: rules-based systems can help real estate and construction companies manage projects by applying rules to optimize scheduling, resource allocation, and material management, but in more complex environments, optimization-based approaches which incorporate business rules as « constraints » may be superior.

Safety management:rules-based systems can help real estate and construction companies manage safety by applying rules to ensure that safety regulations are met and safety incidents are minimized.

Machine Learning

Property valuation: More quickly and accurately assessing the value of properties based on historical data and other relevant factors.

Predictive maintenance: Predicting when equipment is likely to fail, and then feeding those predictions into an optimization-based planning or scheduling system.

Quality control: Monitoring of construction processes and detection of defects in buildings and other structures.

Natural Language Processing

Chatbots and voice assistants: for customer service and support

Real Estate Data Analysis: Natural language search engines for real estate data analysis

Automated report generation and analysis for predictive maintenance and downtime reduction

Computer Vision

Building Inspection: inspecting buildings, detecting potential safety or compliance issues.

3D Modeling: creating 3D models of buildings, improving architectural design and construction planning.

Quality control and Inspection: site safety analysis and asset management

Mathematical Optimization

Project Scheduling: Optimizing the planning and allocation of staff, materials and equipment to construction projects for better forecasting and control of schedules and costs.

Site Selection: Optimization models can be used to identify the optimal location for a new development project. These models can take into account factors such as land cost, proximity to transportation, and availability of utilities to identify the most cost-effective location.

Real Estate Portfolio Optimization: Creation of real estate portfolios based on investment goals, risk tolerand, time horizon, taking into account factors such as occupancy rates, rental income, and maintenance costs.

Business Rules

Compliance: applying rules to ensure complience with industry-specific regulations.

Supply chain management: applying rules to determine the best suppliers and shipping methods for different parts and components.

Risk management: rules-based systems can be used to determine the level of risk associated with different projects and initiatives.

Machine Learning

Predictive maintenance: Machine learning algorithms can be used to predict equipment failure and reduce downtime in aircraft maintenance operations.

Mission planning: Machine learning algorithms can be used to optimize mission planning and execution for military operations, including route planning and target identification.

Fraud detection: Machine learning algorithms can be used to analyze data and detect fraudulent activities such as procurement fraud or financial fraud.

Natural Language Processing

Voice Command and Control: NLP to interpret spoken commands, allowing pilots and operators to control aircraft and equipment using voice commands.

Intelligence Analysis: Natural language processing to analyze and extract insights from reports, news articles, and social media feeds, to inform strategic decision-making.

Machine Translation: translating speech or text, enabling communication and collaboration between multinational teams.

Chatbots and Virtual Assistants: to answer common questions and provide assistance to pilots and operators, reducing the need for human support.

Speech Recognition and Transcription: transcribing speech from cockpit voice recorders, enabling investigators to understand what occurred in the event of an accident or incident.

Computer Vision

Surveillance: detecting and tracking objects in the air or on the ground.

Target Recognition: recognizing and identifying targets, improving accuracy and reducing the risk of collateral damage.

Pilot Assistance: assisting pilots during flight, providing real-time guidance and improving situational awareness.

Maintenance and Inspection: inspecting aircraft components, detecting defects and reducing maintenance costs.

Autonomous Vehicles: guiding unmanned aerial vehicles (UAVs), detecting obstacles and improving safety.

Mathematical Optimization

Production Scheduling: Optimization models can be used to develop production schedules that minimize costs and maximize efficiency. These models can take into account factors such as resource availability, labor costs, and material availability to develop optimal production schedules.

Supply Chain Optimization: Optimizing transportation planning, inventory levels, and delivery times in order to maximize efficiency and minimize lead times.

Dynamic Maintenance Planning: Determining the optimal maintenance policy of each component, forecasting the maintenance period, creating maint. packages & optimal bundling them into monthly/weekly/daily plans in a way that minimizes equipment downtime and maximizes lifespan.

Capacity Planning: Determining the right amount of resources, such as labor, machinery, and materials, required to produce a certain quantity of products in a given time period, while minimizing costs and maximizing efficiency.

Business Rules

Warranty management: management of warranty claims by applying rules to determine if a claim is valid or not and automate the claims processing process.

Supply chain management: applying rules to determine the best suppliers and shipping methods for different parts and components

Production planning: rules-based systems can be used to determine the best sequence of operations and resources needed for each vehicle, however, many production planning and scheduling problems in the autootive industry require much more powerful and flexible optimization technology which incorporates business rules as « constraints. »

Machine Learning

Predictive maintenance: Machine learning algorithms can be used to predict equipment failure and reduce downtime in automotive maintenance operations.

Demand forecasting: Machine learning algorithms can be used to predict demand for different vehicle models and features, allowing companies to optimize their production and supply chain operations.

Customer sentiment analysis: Machine learning algorithms can be used to analyze customer feedback data and improve the overall customer experience.

Natural Language Processing

Customer Service: Chatbots and voice assistants can be used to provide personalized customer service to customers, answering their queries and concerns in real-time.

Sentiment Analysis: analyze customer reviews and feedback on social media and e-commerce platforms, providing insights into customer sentiment and helping automakers improve their products.

Predictive Maintenance: analyze data from connected cars, identifying potential issues before they become major problems and reducing downtime.

Natural Language Search: NLP-powered search engines can help customers find the cars they want, based on their preferences and other criteria.

Automotive Diagnostics: interpret natural language descriptions of automotive issues, providing accurate and efficient diagnostic solutions.

Computer Vision

Autonomous Vehicles: guiding autonomous vehicles, detecting obstacles and improving safety.

Quality Control: identifying defects in products, reducing waste and improving quality control.

Mathematical Optimization

Production Planning & Detailed Scheduling: Developing production plans that minimize costs and maximize efficiency taking into account factors such as production capacity, material availability, equipment and sequencing constraints, customer SLAs and labor costs.

Transportation & Logistics Optimization: Creating efficient supply pickup, loading and route plans taking into account factors such as transportation costs, inventory levels, vehicle capacity and delivery times to get the right quantity and types of parts to the destination on time.

Capacity Planning: Determining the right amount of resources, such as labor, machinery, and materials, required to produce a certain quantity of products in a given time period, while minimizing costs and maximizing efficiency.

Inventory Management: Determining the best inventory levels and ordering schedules, taking into account factors such as location-specific demand forecasts, lead times, and storage costs.

Business Rules

Resource optimization: applying rules to determine the best allocation of resources to maximize production, although depending on complexity, optimization-based approaches which incorporate business rules as « constraints » may be superior.

Quality control: managing quality control by applying rules to analyze production data and identify potential issues.

Compliance: validation of compliance with various industry rules and regulations.

Machine Learning

Predictive maintenance: Machine learning algorithms can be used to predict equipment failure and reduce downtime in mining and processing operations.

Resource optimization: Machine learning algorithms can be used to optimize the use of resources, such as energy and water, in mining operations.

Safety optimization: Machine learning algorithms can be used to analyze data on mining accidents and identify patterns to prevent accidents and improve safety measures.

Natural Language Processing

Automated report generation and analysis: for predictive maintenance and downtime reduction

Chatbots and voice assistants: for customer service and support

Natural language search engines: for mining and metals data analysis

Sentiment analysis: of customer feedback to improve product development and marketing strategies

Computer Vision

Ore Sorting: Mineral & ore analysis, quality control & inspection, improving efficiency and reducing waste.

Safety Monitoring: monitoring safety in mines, improving worker safety and reducing accidents.

Mathematical Optimization

Production Planning & Detailed Scheduling: Developing production schedules that minimize costs and maximize efficiency considering factors like resource availability, labor costs, and material availability.

Resource Allocation: Optimizing the allocation of resources such as labor, equipment, and materials to sites in a way that minimizes costs and improves efficiency.

Supply Chain Logistics Optimization: Creating efficient transportation, logistics & load plans that get the right goods to their destinations on time while optimizing for cost and efficiency.

Dynamic Maintenance Planning: Determining the optimal maintenance policy of each piece of equipment and converting that into efficient maintenance schedules & plans, taking into account factors such as equipment usage, maintenance costs, and expected lifespan.

Business Rules

Reservation and booking management: managing reservations and bookings by applying rules to determine availability, pricing, and other factors.

Loyalty programs: managing loyalty programs by applying rules to determine how points are earned and redeemed.

Customer service: improving customer service by applying rules to determine the best course of action for customer inquiries and complaints.

Machine Learning

Personalized marketing: Machine learning algorithms can be used to analyze customer data and provide personalized recommendations for travel packages, hotel amenities, and promotions.

Customer churn prediction: Machine learning algorithms can be used to analyze customer data and identify customers who are likely to leave, allowing companies to proactively address their concerns.

Natural Language Processing

Customer Service: Chatbots and voice assistants can be used to provide personalized customer service, answering customer queries and concerns in real-time, improving customer engagement and satisfaction.

Personalized Marketing: NLP can be used to analyze customer data and preferences to personalize marketing campaigns, providing a more targeted approach to promotions and discounts.

Sentiment Analysis: NLP can be used to analyze customer reviews and feedback on social media and review sites, providing insights into customer sentiment and helping improve products and services.

Natural Language Search: NLP-powered search engines can help customers find the information they need, based on their preferences and other criteria.

Text Summarization: NLP can be used to summarize long customer reviews, making it easier for businesses to analyze and respond to feedback.

Computer Vision

Customer Analytics: analyzing customer behavior, providing insights into shopping patterns and improving store layout.

Security Monitoring: monitoring security in hotels, ships and resorts, improving safety and reducing the risk of theft.

Mathematical Optimization

Revenue & Yield Management: Create pricing strategies for hotel rooms, airline tickets, and other leisure and hospitality offerings taking into account factors such as demand, competition, and market conditions to maximize revenue.

Tour Planning: Creating cruise or trip itineraries that consider factors such as attraction qty/quality, port availability, customer demand, and travel time to balance across revenue and customer satisfaction.

Facility/Venue Layout Design: Strategic placement of rooms, amenities, and service areas within hotels, resorts, or restaurants to ensure smooth flow, maximize space utilization, and create a welcoming environment for guests.

Workforce Planning & Scheduling: Assigning employees to locations, shifts and activities based on demand, skills, and availability.

Business Rules

Claims processing: automating claims processing by applying business rules to determine if a claim is valid or not.

Care management: automatically identifying patients who need intervention and applying appropriate rules to determine the best course of action.

Compliance: ensuring that healthcare organizations’ processes and procedures comply with regulations.

Machine Learning

Medical imaging: helping healthcare providers analyze medical images such as X-rays, MRI scans, and CT scans to detect and diagnose conditions.

Patient risk assessment: helping to predict the risk of patient readmissions, hospital acquired infections, and other adverse outcomes.

Personalized treatment plans:helping providers create personalized treatment plans for patients by analyzing their medical history, genetics, and other relevant data.

Natural Language Processing

EHR: Clinical documentation and electronic health record (EHR) management

Medical Coding and Billing

Patient interaction and engagement: through chatbots and voice assistants

Clinical decision support systems: using NLP to analyze patient data

Computer Vision

Medical Imaging: detecting abnormalities and helping with diagnoses.

Outbreak Monitoring: analyze map images to understand and predict disease spread

Surgery Assistance: assist surgeons during procedures, providing real-time guidance and improving accuracy.

Patient Monitoring: monitor patients, detecting changes in vital signs and alerting medical staff to potential issues.

Mathematical Optimization

Hospital Resource Allocation: Allocation and scheduling of medical staff, diagnostic equipment and operating rooms to ensure optimal patient care and maximize efficiency.

Staff Planning & Scheduling: Creating optimized workforce plans and operational schedules for hospital or field staff, considering demand, skills, geography and other factors in order to balance efficiency and service level objectives.

Clinical Trial Design: Optimization of clinical trials design to improve the speed and accuracy of drug development.

Maintenance Planning: Dynamic planning of equipment maintenance based on sensor data, creating maint. packages & optimal bundling into monthly/weekly/daily plans.

Tactical Medical Representative Visit Planning: Defining the optimal routes for medical representatives visits to customers, respecting customers priority, visits frequency and available time windows, to minimize travel time and maximize visits per day.

Strategic Design: Optimization of hospital layout and design to improve patient flow and reduce wait times.

Business Rules

Equipment maintenance: applying rules to determine when maintenance is needed and which equipment requires attention, – but for complex asset maintenance planning problems, optimization-based approaches which incorporate business rules as « constraints » may be superior.

Product design and configuration: helping with product design and configuration by applying rules to ensure that products meet specifications and are configured correctly for different use cases.

Quality control: helping manage quality control by applying rules to analyze production data and identify potential issues.

Machine Learning

Predictive maintenance: Machine learning algorithms can be used to predict equipment failure before it happens. By feeding these predictions into a maintenance optimization system, one can reduce downtime and maintenance costs.

Inventory optimization: Machine learning algorithms can be used to help optimize inventory levels by predicting demand

Energy efficiency: Machine learning algorithms can be used to optimize energy usage in manufacturing operations and reduce costs.

Natural Language Processing

Automated report generation and analysis: for predictive maintenance and downtime reduction

Chatbots and voice assistants: for customer service and support

Equipment analysis: Natural language search engines for equipment data analysis

Sentiment analysis: of customer feedback to improve product development and marketing strategies

Computer Vision

Predictive Maintenance: monitoring industrial equipment, detecting potential issues and improving maintenance.

Process Automation: automating industrial processes, improving efficiency and reducing labor costs.

Mathematical Optimization

Production Scheduling: Optimization models can be used to develop production schedules that minimize costs and maximize efficiency. These models can take into account factors such as resource availability, labor costs, and material availability to develop optimal production schedules.

Supply Chain Optimization: Optimizing transportation planning, inventory levels, and delivery times in order to maximize efficiency and minimize lead times.

Facility Location Planning: Determining the optimal location for a new industrial equipment facility. These models can take into account factors such as land cost, proximity to transportation, and availability of utilities to identify the most cost-effective location.

Technician Dispatching, Routing and Scheduling: Dynamic job/task assignment, scheduling & routing of engineers and technicians based on location, skills, job priority, service level, parts availability, etc in a way that optimizes around various business KPIs.

Dynamic Maintenance Planning: Determining the optimal maintenance policy of each component, forecasting the maintenance period, creating maint. packages & optimal bundling them into monthly/weekly/daily plans in a way that minimizes equipment downtime and maximizes lifespan.

Business Rules

Risk management: applying rules to determine the level of risk associated with different types of investments and transactions.

Fraud detection: BRMS can help financial institutions detect fraudulent activities by applying rules to identify suspicious transactions and flag them for investigation.

Credit scoring: assessing creditworthiness by applying rules to analyze credit data and generate credit scores.

Machine Learning

Fraud detection: detection & prevention of fraud by analyzing transaction data and identifying suspicious patterns.

Credit scoring: assessing the creditworthiness of loan applicants by analyzing credit history and other relevant data to gauge creditworthiness.

Investment analysis: analyzsis of market trends to identify predictive signals that can inform investment opportunities.

Natural Language Processing

Sentiment analysis: of news and social media to predict market trends

Fraud detection: and prevention using NLP to analyze text data

Chatbots and voice assistants: for customer service and support

Natural language search engines: for financial research and analysis

Computer Vision

Fraud Detection: check and document analysis for detecting fraudulent activity and preventing financial losses.

Facial Recognition: biometric authentication and identification, improving security and reducing the risk of fraud.

Mathematical Optimization

Portfolio Optimization: Optimization of investment portfolios based on specific investment goals, time horizon, risk tolerance and other goals and constraints – sometimes used in algorithmic trading.

Asset-liability Management: Supporting decisions about how to manage assets and liabilities in a way that maximizes returns while minimizing risk.

Avez-vous déjà remarqué que de nombreuses listes de technologies et de cas d’utilisation de l’IA tendent à négliger les techniques d’optimisation mathématique ? Alors que ces listes et les médias en général mettent généralement l’accent sur l’apprentissage automatique, le traitement du langage naturel, la vision par ordinateur et d’autres applications de l’IA à la mode et souvent controversées, l’optimisation est souvent absente de la conversation.

Pourquoi est-ce important ? Lorsqu’ils sont évalués dans l’ensemble des industries, les cas d’utilisation basés sur l’optimisation mathématique sont non seulement parmi les plus robustes et les plus durables, mais ce sont aussi les applications qui ont le plus d’impact et le meilleur retour sur investissement par rapport à toutes les autres applications logicielles basées sur l’IA. En effet, les systèmes alimentés par l’optimisation ne se contentent pas de vous dire quand la demande est la plus forte, comment le sentiment à l’égard de votre marque a changé, quand un client va se désabonner ou quand une récolte va probablement mûrir (suivie d’une panne de votre moissonneuse-batteuse, le tout au milieu d’une pénurie de main-d’œuvre, bien sûr !) Au lieu de cela, les systèmes logiciels optimisés prescrivent en fait comment programmer vos employés, planifier votre maintenance, séquencer votre production, charger votre remorque, fixer le prix de votre produit ou acheminer vos camions – même à court terme, en réponse à des perturbations imprévisibles. C’est pourquoi nous parlons d’analyse prescriptive, car il s’agit de prescrire ce qu’il faut faire avec toutes les informations dérivées de toutes les autres techniques, de manière à se rapprocher le plus possible des objectifs de l’entreprise sans en enfreindre les contraintes.

C’est pourquoi nous sommes ravis de vous présenter notre nouvelle infographie interactive, qui présente certaines des applications d’IA les plus courantes, regroupées en cinq catégories de technologies d’IA dans 16 secteurs d’activité différents. Bien que cette infographie soit loin de constituer une liste exhaustive des méthodes, des secteurs ou des cas d’utilisation de l’IA, et qu’elle ne prédise pas non plus les cas d’utilisation de demain, nous espérons qu’elle constituera une ressource précieuse pour les chefs d’entreprise, les innovateurs, les étudiants et tous ceux qui souhaitent voir le paysage actuel de l’IA sous un angle plus large

DecisionBrain est un fournisseur de premier plan de logiciels avancés d’aide à la décision utilisés pour résoudre les problèmes d’optimisation de la chaîne d’approvisionnement, de la planification de la main-d’œuvre et de la maintenance, de l’ordonnancement et de la logistique les plus difficiles au monde. Avec des années d’expérience dans l’apprentissage automatique, la recherche opérationnelle et l’optimisation mathématique, DecisionBrain fournit des systèmes d’aide à la décision sur mesure là où les applications packagées ne suffisent pas. Contactez-nous pour en savoir plus sur nous et nos solutions !