Blog

Trying to Make Sense of Agentic AI in Supply Chain

Over the past twenty-plus years, I’ve seen supply chain management from many angles – running operations teams, working on projects as a consultant, and developing advanced analytics software to improve planning and execution. That combination of experiences has made me both optimistic and cautious when it comes to new technology hype.

Each cycle (Digital Twins, Continuous Planning, AI/ML, Blockchain, etc.) brings another round of bold claims. What is real, and what is marketing hype? The latest of these is agentic AI.

Per Gartner, “Agentic AI systems autonomously plan and take actions to meet user-defined goals. Agentic AI offers the promise of a virtual workforce that can offload and augment human work.”

Nice definition. From there, I started reading with a goal of trying to understand what is real and what isn’t. Could agentic AI actually make a real difference in the messy world of supply chain planning and operations? In my experience, software typically creates ideal states and planners are left to deal with reality and exceptions.

What follows is my attempt to facilitate some clarity: what agentic AI is in supply chain, what’s working today, and where the hard problems still lie.

Where Planning Stands and How it’s Changing?

If you’ve worked in supply chain operations, you know the pattern. Advanced analytics and optimization engines set the parameters—inventory targets, safety stocks, reorder points, transportation plans.

As reality shifts, planners handle the variation – expediting, reallocating, adjusting production, and overriding the system when assumptions no longer hold, using reports and dashboards. It’s a reliable model for many organizations, but it’s reactive. Most environments still depend on batch updates and manual review, so a supplier delay, demand spike, or port disruption can take hours or days to appear.

Agentic AI aims to shorten that gap. The optimization and rules engines we already trust haven’t changed, but the way they’re driven can.

A reasoning layer powered by an LLM can interpret what changes mean (“temporary weather delay” versus “extended labor dispute”), convert that context into updated constraints, and feed the existing engines with current conditions rather than last week’s assumptions. The result is not new math; it’s better timing and alignment between what’s happening and what the solvers are asked to do.

How This Differs from “Advanced Planning”

Traditional advanced planning (rules, optimization, ML) typically runs on structured cycles: forecast, plan, execute, adjust. Agentic AI doesn’t replace that foundation; it changes the cadence and control. Instead of a planner deciding when to refresh a plan, the system determines when a re-plan is warranted, what kind of intervention is appropriate, and whether to simulate alternatives, re-optimize, or simply alert a human.

This is a shift from scheduled computation to something like continuous prioritization. The intelligence moves from fixed intervals to a feedback loop that perceives, reasons, and acts as conditions change.

In practical terms, that means a system that can monitor live data (like shipment delays or supplier updates), interpret what those events mean, trigger an optimization run automatically, and present an updated recommendation for review or execution. Instead of a fixed frequency–there is a new planning rhythm based on reality that allows humans to focus on the most important decisions.

For example, if a hurricane threatens a key supplier region, an agentic AI system could interpret the weather alert, identify at-risk components, trigger a re-optimization of supply routes, and generate a recommended reroute plan for human review—all before the disruption hits operations.

What’s Real vs. Hype

It’s not practical today for any large enterprise to run a fully autonomous, end-to-end, agentic “self-driving” supply chain. That level of automation would require exceptionally clean, real-time data, deep system integration, and organizational trust that most companies don’t yet have.

Gartner’s 2025 forecast underscores this maturity gap—predicting that by 2030, 50 percent of cross-functional supply-chain management solutions will include agentic-AI capabilities.

What is practical now are semi-autonomous, integrated agents: AI agents that monitor processes, detect disruptions, and automatically re-run optimizations or provide recommendations as a complement to existing planning and execution systems rather than a replacement.

Here is a great article from SAP that references use cases at Walmart, Amazon, and DHL. All three are obviously heavyweights–but they are excellent examples of using agentic AI to identify issues and recommend/action improvements in an automated manner.

How Agentic Supply Chains Work

Here is a view of the architecture that makes up an Agentic AI Planning System:

- Data and Events Layer: Stream real-time data from ERP, WMS, and supplier systems.

- Reasoning Layer: Use an LLM to interpret events, determine impact, and decide when re-planning is needed.

- Optimization Layer: Connect to an algorithm/solver to compute new recommendations.

- Action Layer: Push changes through APIs or RPA bots into planning or execution systems.

- Supervision Layer: Maintain human approval and documentation — the AI should always explain its reasoning.

Much of this isn’t new, but what is new is the introduction of LLMs as a reasoning layer and the integration across these layers that is creating this capability. Here are three technology trends that are helping make this possible.

Large Language Models for Context and Reasoning

LLMs aren’t replacing solvers; they’re bridging the gap between the unstructured world of supply chain communication and the structured logic of optimization. They can extract meaning from an email or a shipment status, map it to a relevant constraint, and feed that into a solver. They also improve transparency, explaining why a particular recommendation was generated — something traditional optimization tools have often struggled to do. That said, they can also misinterpret incomplete or new data.

Decision Engines for Quantitative Optimization

Optimization remains the core of supply-chain decision-making. Optimization and rules continue to handle the workload of allocation, routing, and scheduling. What’s changing is how they’re being used. LLMs and reasoning layers can now dynamically adjust inputs and constraints before re-running an optimization model—essentially acting as a cognitive interface that keeps models aligned with reality.

Event-Driven, API-Based Architectures

This is an area I have limited technical knowledge, but to enable agentic behavior depends on timeliness. Real-time event streaming and API connectivity allow systems to detect and react to change immediately, and technology advancements are making that possible. IoT protocols have been present and leveraged for a while, but these improvements are extended for ‘unstructured’ data. This allows an organization to transform the planning cycle from periodic to continuous. This article does a good job of outlining the improvements in this area.

How do I get one?

Now that we understand the core layers, the next question is where to source them. Some organizations are building custom agentic extensions, layering reasoning and optimization logic on top of existing systems through APIs and solvers. Others are leveraging vendor modules or add-ons that provide event-driven re-planning within established ecosystems.

Both approaches can work. The key is aligning the choice with your data maturity, internal skill base, and process readiness. Success depends as much on process and governance as on the technology itself too.

Where Things Get Hard

While the concept is promising, there are some significant hurdles that will slow development and adoption.

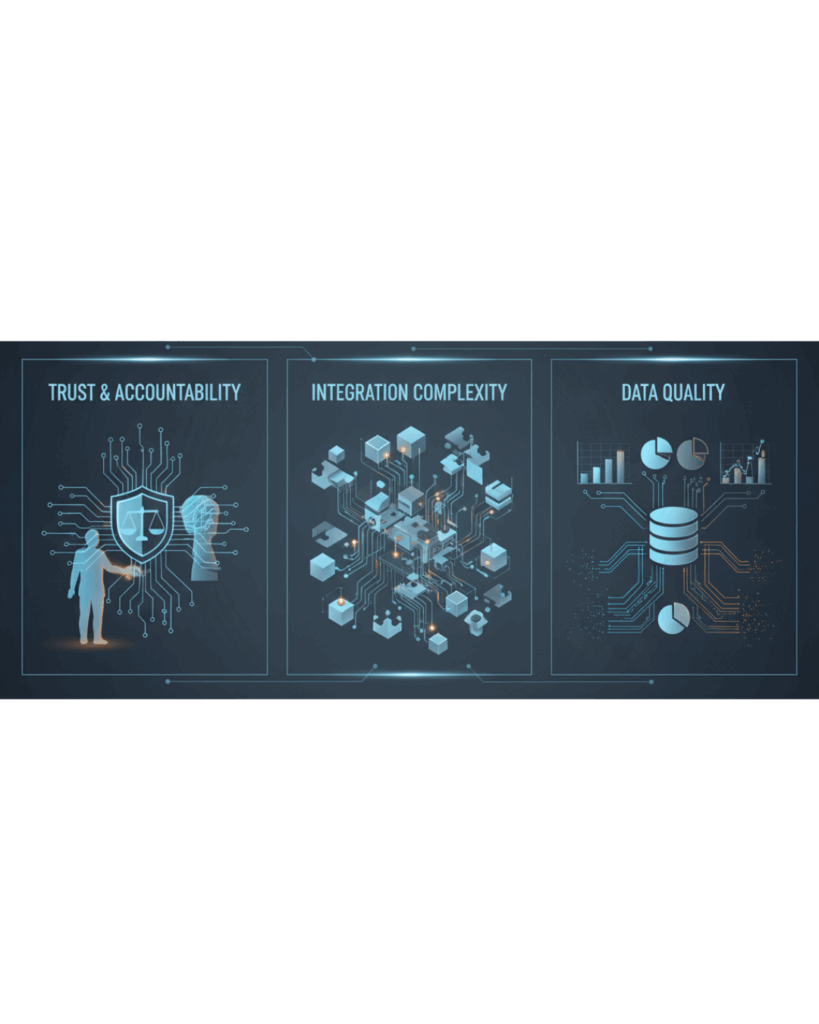

Trust and Accountability

When AI starts making or executing decisions that affect millions in inventory, service, or production cost, who’s responsible when it’s wrong? Without clear accountability, most organizations will keep humans firmly in the loop. Building trust requires transparency, auditability, and well-defined escalation rules. LLMs can still misinterpret things and make mistakes.

Integration Complexity

Most enterprises run on legacy systems that weren’t built for event-driven automation. It’s not just about connecting APIs — it’s about aligning data models, timing, and business processes across planning, manufacturing, and logistics platforms.

Data Quality

Agentic systems need clean, real-time data. Many companies still struggle with basic data accuracy, missing lead times, or inconsistent inventory updates. Without a solid foundation of reliable inputs, even the smartest reasoning layer will generate unstable or misleading outputs.

A Practitioner’s Outlook

In the near term, the most meaningful benefit of agentic AI will be faster, more consistent decisions.

Planners will spend less time chasing exceptions and more time validating and refining system-generated recommendations. As data quality and confidence grow, many routine adjustments will move from human review to automated execution.

This shift will happen in phases:

- Starting with assistive copilots that summarize and suggest

- progressing to supervised autonomy that manages low-risk adjustments

- Ultimately reaching trusted systems that act within defined guardrails—escalating only the complex or high-impact exceptions.

Organizations that combine this technological progression with strong data discipline and clear decision governance will gain a lasting operational advantage.

Final Thoughts

Agentic AI represents an important step forward in how supply chains can operate, but it won’t be a revolution overnight. In my mind, we were always working toward something like this, but the LLM piece is truly new.

While LLMs have improved, they can still make mistakes. The shift from “human-in-the-loop” to something that looks like autonomous systems will be slow. Most organizations will adopt hybrid approaches for years to come, where AI handles the repetitive adaptations and humans manage strategy, trade-offs, and exceptions.

All in all, these solutions won’t replace planners but augment them in the near-term, and this is where the real opportunity lies. Companies that leverage this technology but compliment with process-work and accountability will make faster, better-informed decisions and free their people to focus on higher-value work. The next generation of supply chain professionals will increasingly work alongside some amazing systems that think, learn, and act—just not entirely on their own.

Here is a link that illustrates a simple agentic AI system for a toy supply chain problem in a Colab Notebook. Here is a doc output of the notebook if the code is overwhelming. Thanks for reading!

Addendum: Building It Taught Me More Than Reading About It

I often like to build mini demos to learn, illustrate concepts, etc. After reading and watching videos on Agentic AI, I built a prototype (using LLMs)—a supply chain planning system where an LLM interprets events like « crisis in Northeast, prioritize their demand » and drives mathematical optimization. The concept is straightforward: natural language understanding meets quantitative decision-making. The reality is messier.

The notebook demonstrates a simplified network with constrained capacity to force trade-offs. The system establishes a baseline optimal plan, then users input events in natural language. The LLM analyzes each event, decides whether replanning is warranted, extracts structured parameters (capacity changes, demand shifts, customer priorities, cost adjustments), and triggers re-optimization. It’s intentionally simple to illustrate the core mechanics without production complexity.

The real challenge is the translation layer. When you say « meet all demand in this region, » the LLM understands the business intent, but the optimizer needs precise numerical parameters. We used JSON as the bridge, but getting the LLM to consistently output correct structure required extensive prompt engineering.

The examples in your prompt become training data for this specific task, and even with careful design, the LLM would sometimes hallucinate changes that weren’t mentioned or miss critical signals entirely. You’re essentially teaching the LLM your schema through examples, discovering edge cases through iteration.

You’re not building one system—you’re building two that must communicate through a carefully designed protocol, and that protocol becomes the most critical piece.

When it fails, debugging is ambiguous: is the LLM misinterpreting? Is the translation wrong? Is the model formulation off?

The power is real once it works: the system handles novel scenarios through reasoning rather than hardcoded rules. But getting there requires accepting that bridging natural language with structured decision-making is genuinely hard, and this translation problem will be central to any agentic system that attempts it. Anyone building similar systems will face these same challenges.

About the Author

Justin brings over 20 years of experience in analytics, supply chain management, professional services, and manufacturing operations to DecisionBrain. His career has centered using data and analytics to improve operations. He has held leadership positions at Accenture, Caterpillar, Opex Analytics, and Coupa Software (Llamasoft). Justin has a BSc in Engineering Mechanics from the University of Illinois and a MSc in Analytics from the University of Chicago.

FAQ

Agentic AI uses large language models (LLMs) to autonomously plan, reason, and act toward business goals. It adapts in real time, turning static planning into dynamic decision-making.

It’s used to monitor disruptions, re-optimize plans, and recommend actions instantly. Companies like Amazon and DHL use it to rebalance inventory and maintain service levels automatically.

It’s when an AI generates outputs that sound correct but aren’t based on facts. In supply chains, this can lead to wrong assumptions—making human validation essential.

Humans oversee, validate, and manage complex trade-offs. AI handles routine adjustments; planners focus on strategy and exceptions.

At DecisionBrain, we deliver AI-driven decision-support solutions that empower organizations to achieve operational excellence by enhancing efficiency and competitiveness. Whether you’re facing simple challenges or complex problems, our modular planning and scheduling optimization solutions for manufacturing, supply chain, logistics, workforce, and maintenance are designed to meet your specific needs. Backed by over 400 person-years of expertise in machine learning, operations research, and mathematical optimization, we deliver tailored decision support systems where standard packaged applications fall short. Contact us to discover how we can support your business!

Ready to transform your operations?

Contact DecisionBrain today to discover how our solutions can help your business thrive.