Overview

Production planning and scheduling optimization for high-end Printed Circuit Boards.

A fast-growing producer of high-end Printed Circuit Boards (PCB), used in a wide variety of applications including automotive, industrial, computer, and telecom systems. Its customers include some of the world’s biggest names in automotive and electronics.

The competitive advantage relies on product quality, manufacturing, and operational excellence.

PCB production planning and scheduling solutions consolidate and analyze real-time data from operations and apply a scientific approach to decision-making to reach global (plant level) and local (work center level) objectives. Since all the work centers are connected, a global plan that considers all work centers is necessary to optimize production. Planners encounter significant difficulties in developing manual plans that can cope with the complexities of considering all work centers at the same time.

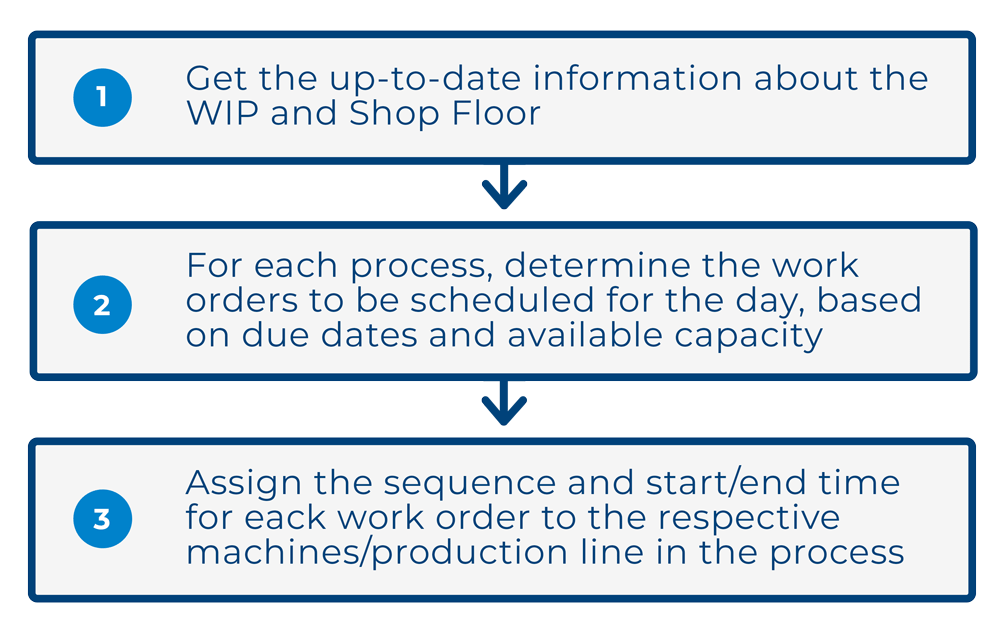

Planning logic for PCB production

Before engaging with DecisionBrain, production planning and scheduling was performed manually by over one hundred planners and focused only on one work center at a time. This lack of coordination across work centers created multiple issues:

- Heavy dependency on the experience of senior planners

- Downstream bottlenecks due to upstream product choice

- Infeasible plan violating different constraints

- Due date ignored at upstream work centers

- Large WIP buffers needed

Solution

A system to improve on-time customer delivery and operational efficiency.

DecisionBrain was tasked with creating a system that provides a consistent, systematic approach to production planning and scheduling according to the business needs. Overall the project aimed at optimizing production planning across all work centers to improve operational KPIs. The solution consisted of developing two optimization engines, one for Global Planning and one for Scheduling.

Global Planning Engine: This engine has visibility over all work centers and all work orders and coordinates the overall plan. Each work center does not only have a local optimization objective (such as maximize throughput, minimize changeover), but also follows a global orchestrated guidance, which leads to:

- Balanced upstream product choice to ensure downstream process efficiency

- Guaranteed feasibility respecting all constraints

- Increased on-time delivery

- Balanced production of easy and difficult products

- Minimized outsourced quantity

- Reduced WIP

Scheduling Engine: This engine is tasked to optimize production KPIs while respecting all constraints. With our solution:

- Good quality production plan obtained in a few minutes (even for large work centers with 80+ machines)

- User-friendly interactive Gantt to easily modify the plan

- Possibilities to perform simulations based on different criteria and priorities

- Improved production efficiency

Results

Planners benefit from the system transparency and efficiency

Besides optimized production plans and schedules, the system delivers standardized production-related data, automated production time computation and real-time feasibility checking. Planners benefit from the system transparency and efficiency as well as from the collaborative environment that the solution enables. Additionally, a standardized and consistent system enables anyone to view and check the production plan without the need of several years’ experience.

The project is in its final phase of implementation and has provided strong preliminary results.