20+ years of experience in building tailored Manufacturing and Supply Chain optimization solutions leading to 30-50% improvements against manual/heuristic plans. Improve efficiency along different dimensions of manufacturing operations.

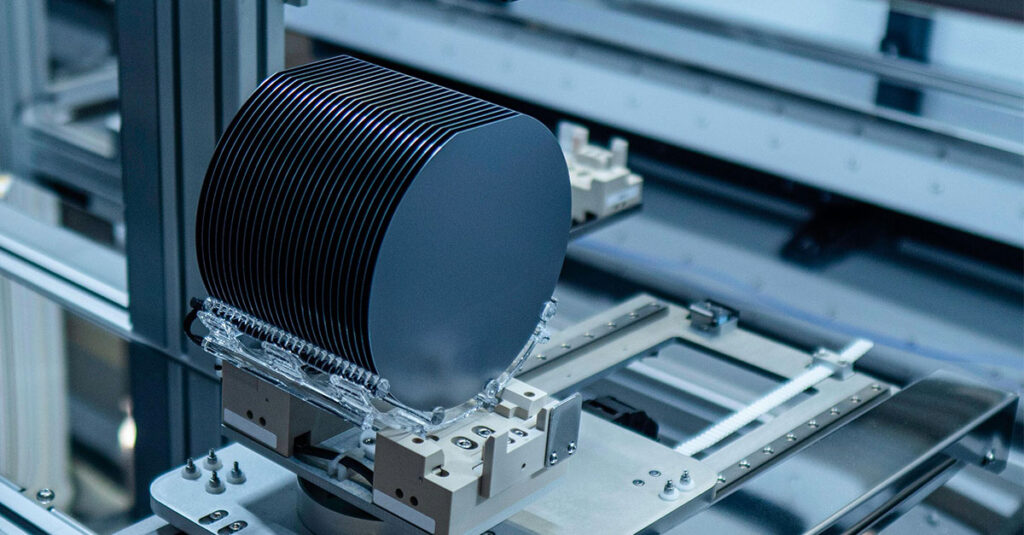

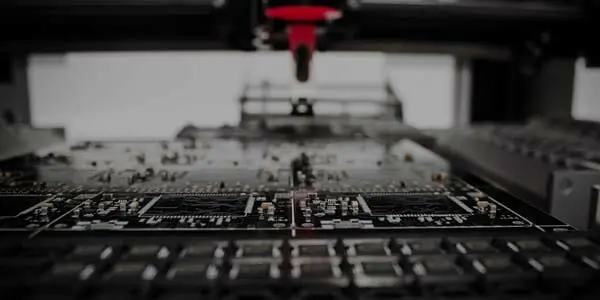

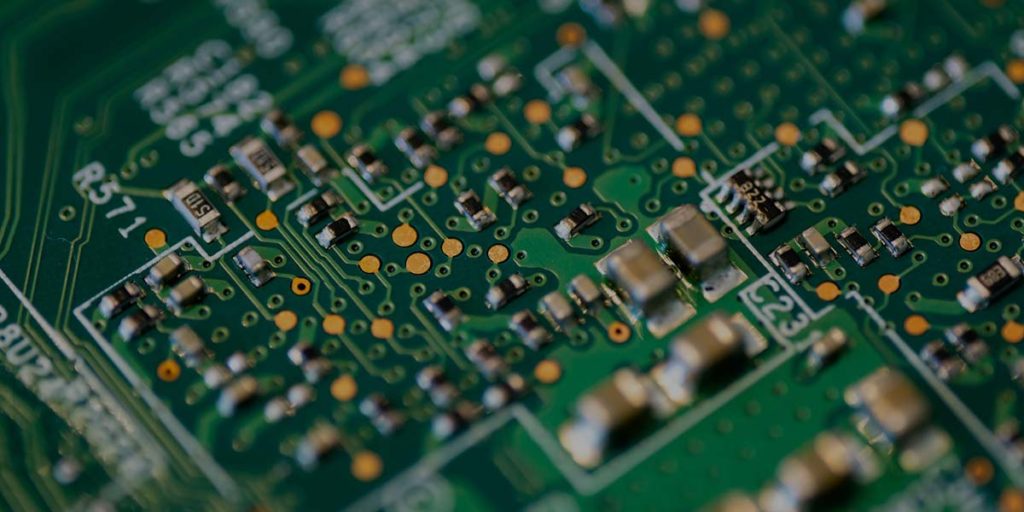

Electronic and Semiconductors

Production Scheduling Optimization for semiconductors and printed circuit boards

Optimizing WIP and Lead Times are two critical aspects of Semiconductor and Electronics manufacturing. Given the complexity of some production processes, optimizing layout and placement of compatible part numbers is of critical importance.

Apparel

Integrated Production Scheduling and Shipment for leading apparel companies

Our solution manages to optimize throughput by integrating production and shipment scheduling. It intuitively enables planners to consider sewing learning curve impact on the overall production process, and allows them to optimally integrate demand variability with production and shipping modes lead-times.

Product Packaging

Supply Chain Planning and Production Scheduling for a leading provider of recyclable plastic packaging for the US market

Our solution provides a holistic view across all dimensions (demand, production and warehouse space) and supports planners to quickly and easily address customers’ requests at a minimum cost.

Auto Parts

Paint Line Scheduling for Auto Parts Production

Our solution allows to quickly create high quality operational schedules that meet production cost targets while coping with urgent and short-term customer orders.

Advanced Manufacturing Planning & Detailed Scheduling Software Demo

Advanced Planning and Production Scheduling software system used by a packaging company for make-to-stock and make-to-order products. Resulted in reduced production costs, higher throughput, reduced waste and greater responsiveness to demand volatility or machine breakdowns.

Master planning & scheduling system optimizes simultaneously across multiple work centers while considering machine and equipment limitations, tight warehouse capacity, raw material maturity and shelf life and production of both intermediate and final BOMs.